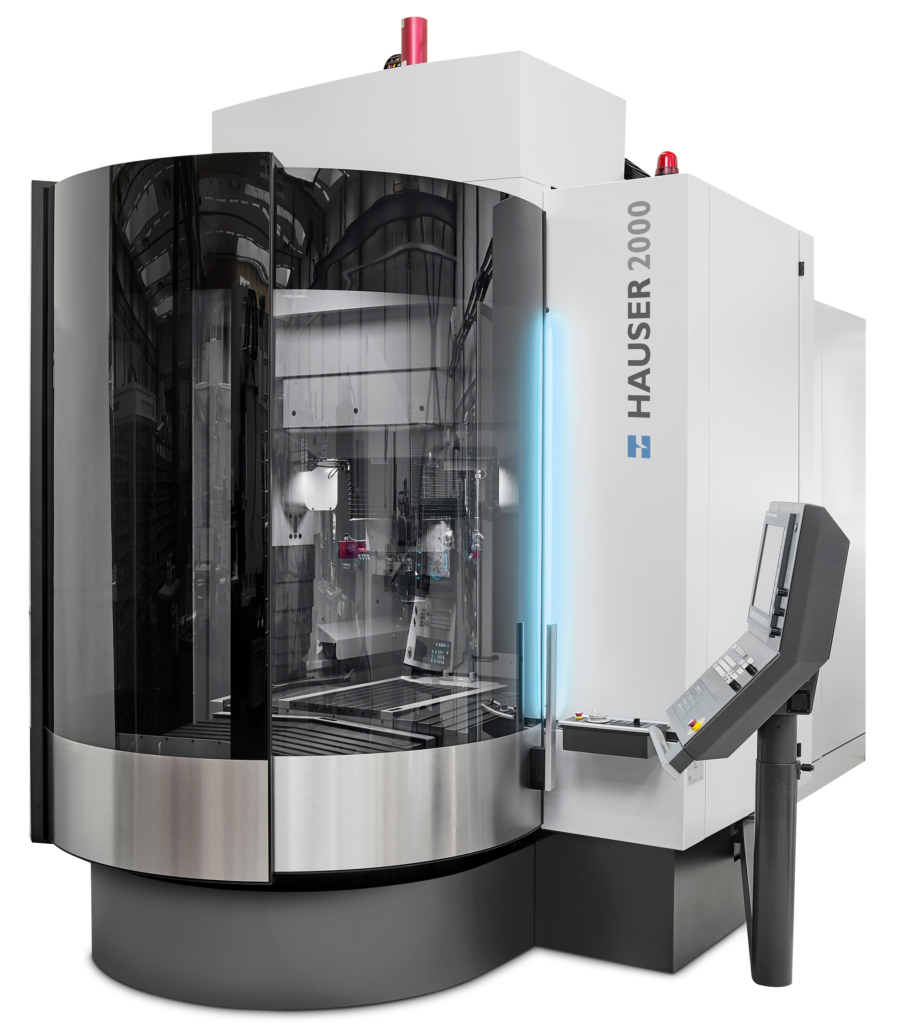

HAUSER 2000

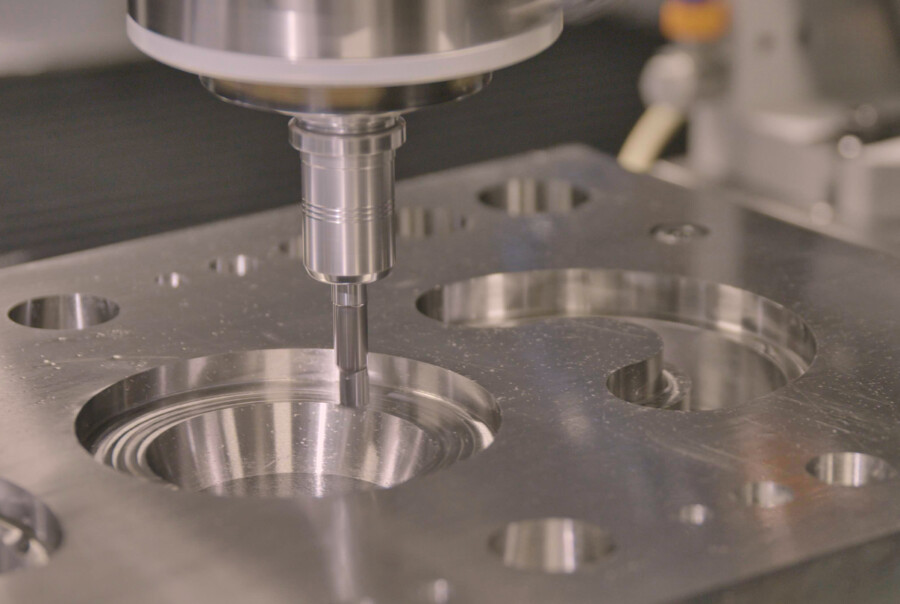

Jig grinding

Double frame construction increases the rigidity of the machine

6-axis machine configuration, optional 8-axis possible

HAUSER

When it comes to parts with the highest demands on shape, dimensional and positional tolerances or complex component geometries, jig grinding technology is in demand. The machines of our brand Hauser meet all requirements thanks to their construction of robust, torsion-resistant modules and consistent design for thermal stability. Through continuous technical development, we ensure constant improvements in machining precision in order to meet future requirements.

FEATURES AND OPTIONS

- Measuring probe for automatic best-fit measurement of workpieces

- Customised A and A-B rotary and rotary-swivel axes are available as additional units

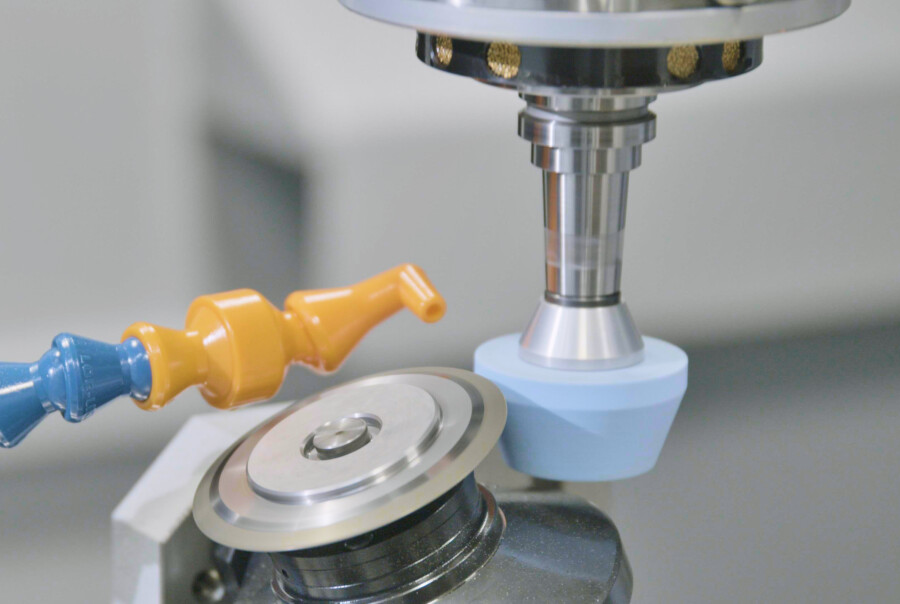

- Grinding motor 70HS with its extremely wide application range from 9000 min-1 to 70000 min-1.

- CBN dresser with HF drive, for conditioning (dressing) ceramic and resin-bonded CBN grinding wheels

- MSS – multi-sensor system for automatic suppression of “air grinding” and for automatic grinding wheel calibration

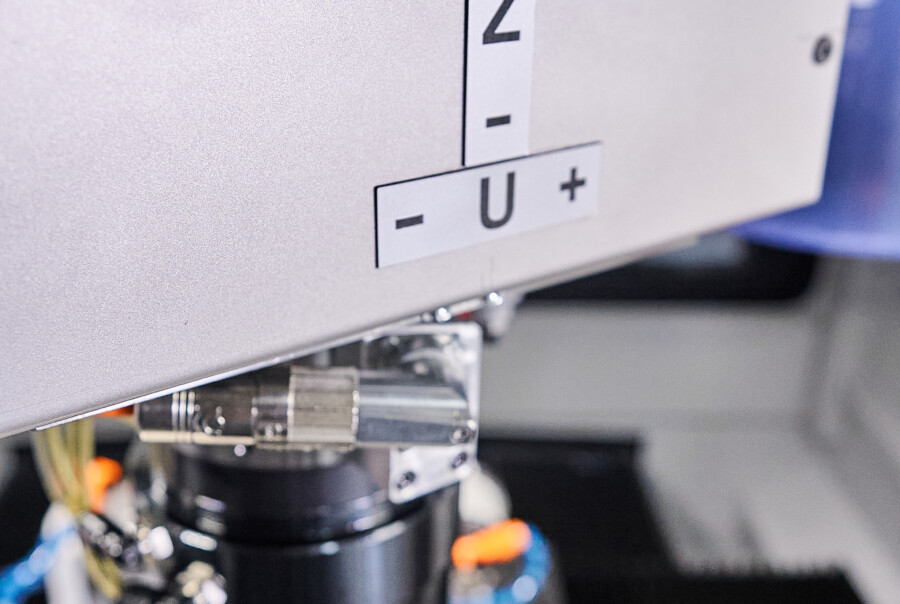

- Automated taper grinding with the aid of Z-U axis interpolation

CONTROL AND SOFTWARE

The HAUSER 2000 is equipped with the FANUC Series 30i-B:

- FANUC 30i-B with 15 inch touch display

- Intuitive operation thanks to WHITE-Solution

- Clear screen pages

- Online operating and maintenance instructions

Technical data

Specifications HAUSER 2000

Supply voltage

400 V / 460 V

Power consumption depending on the equipment

15-32 A

Space requirement / length x width

2.4 m x 5.4 m

Total weight

12'500 kg

Work area

Adjustment range X, Y

550 x 300 mm

Vertical adjustment of the grinding head (W)

450 mm

Passage between table surface and U-axis Grinding motor support plate

745 mm

Passage between table surface and (70HS) grinding motor nose Tool holder

0 - 550 mm

Grinding diameter with planetary grinding, with grinding disc Ø 40 mm / 70HS

Grinding motor 70HS in U-axis centre position, in automatic mode

144 mm

with cantilever plates

360 mm

Grinding diameter with planetary grinding, with grinding disc Ø 100 mm / 40HS

40HS grinding motor in U-axis centre position, in automatic mode

194 mm

40HS grinding motor in U-axis offset position, in semi-automatic mode

360 mm

Conical grinding, included angle, divergent or convergent (option)

120 degree

Table

Usable area

650 x 400 mm

T-slots, width

8, 10 mm

Permissible load

300 kg

Feed rate Speed

Table and saddle X, Y

Adjustment speed

8 000 mm/min

Processing speed

0 - 4 000 mm/min

Grinding spindle Z, C, U

Diameter of the spindle sleeve

125 mm

The basic machine is prepared for the following grinding spindle speeds

Adjustment speed

8 000 mm/min

Grinding spindle Z, C, U

Diameter of the spindle sleeve

125 mm

The basic machine is prepared for the following grinding spindle speeds

for electric grinding motor 40HS, infinitely adjustable and programmable

3 600 - 45 000 min-1

for electric grinding motor 70HS, infinitely adjustable and programmable

8 000 - 70 000 min-1

Device for use with air-driven grinding turbine T15

up to 150 000 min-1

C-axis planetary speed

Planetary speed, infinitely adjustable and programmable

1 - 350 min-1

Tracking mode, AC servo drive

up to 10 min-1

Z-axis as alternating stroke

Z-stroke movement, infinitely adjustable

Vmin. 0,500 mm/min / Vmax. 26 000 mm/min

Z-stroke frequency

Max. 10 Hz

Z-stroke length, infinitely adjustable

0,1 - 170 mm

U-axis, radial infeed range in motorised CNC operation

von -3 bis zu +47 mm

Control system

Manufacturer / Type

Fanuc 30i-B

Machine operation

HMI

WHITE Solution

Product competence

Request

I am interested in a KELLENBERGER machine