VOUMARD 1000

Flexible machine design with two linear axes and two rotary axes

Kinematically flexible machine design has two linear axes and two rotary axes

Large number of processing variants

HIGH PERFORMANCE FOR COMPLEX GRINDING TASKS

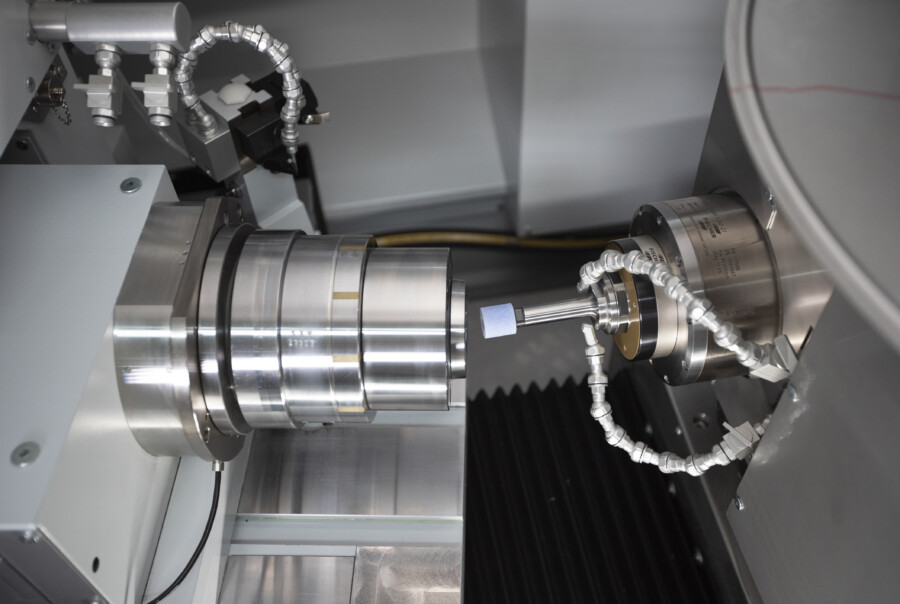

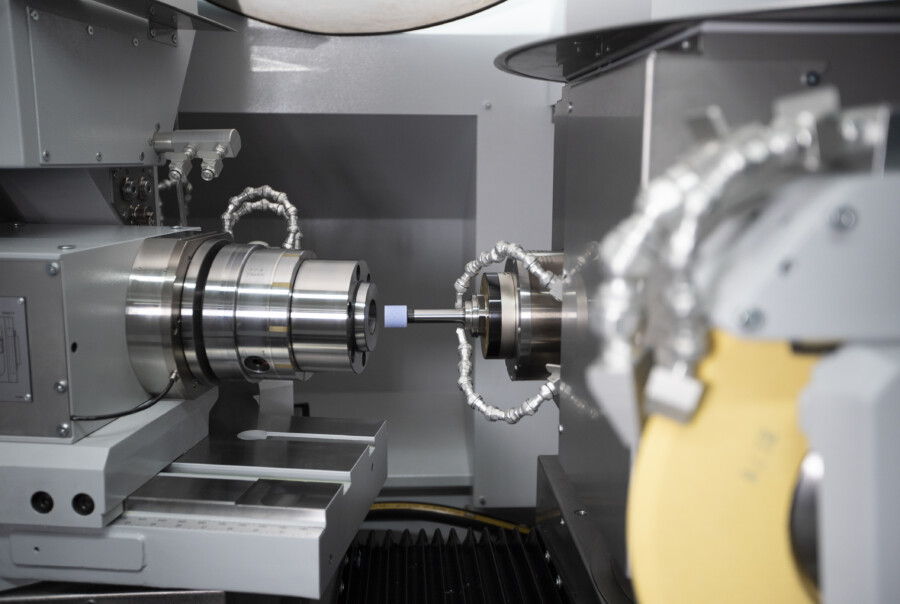

The VOUMARD 1000 is optimized for flexible, universal internal and external cylindrical machining of complex workpieces. High-precision chucks, steady rests and fixtures for shoe grinding allow almost any workpiece shape to be machined and several internal and external grinding operations to be carried out in a single clamping operation. The workpieces range from the smallest individual parts for injection systems in car engines, ball bearing rings and gears to hydraulic components and complex components in machine tool construction, such as spindles.

The kinematically flexible machine design of the VOUMARD 1000 has two linear axes and two rotary axes. The hydrostatic linear axes with newly developed HYDROLIN® guides are backlash-free for positioning accuracies in the nanometer range. The high-precision hydrostatic B-axes also perform all necessary movements of the dressing and measuring devices. This flexibility makes a large number of machining variants possible and shortens set-up times. The spindle turret on the B1 axis is equipped with a uniquely compact grinding spindle head with a flexible internal grinding spindle arrangement for a maximum of four grinding spindles.

Operator guidance is via an intuitive 19″ touchscreen interface of the latest FANUC 31i-B CNC control system. The innovative BLUE Solution software enables even inexperienced operators to program quickly and intuitively.

FEATURES AND OPTIONS

- Innovative HYDROLIN®

- Hydrostatic guides

- Linear motor with thermodynamics

- New kinematic machine design with two linear and two rotating axes

- Reduction to two high-end axes in the sub-micron range

- Compact machine design

CONTROL AND SOFTWARE

The VOUMARD 1000 is equipped with the FANUC31i-B:

- FANUC 31i-B with 19 inch touch display

- Intuitive operation thanks to BLUE Solution with OBJECT Guide and ISO Guide

- Clear, self-explanatory screen pages

- Integrated technology calculator

- Online operating and maintenance instructions

SUPPORT AND RESOURCES

Technical data VM1000

Specifications

Center width (workpiece length)

600 mm

Centre height

150 mm

Workpiece diameter

< 150 mm / < 300 mm

Workpiece weight

50 / 100 / 200 kg

Load when working with a chuck

100 / 320 Nm

Supply voltage

400 V / 460 V

Power consumption depending on the equipment

35 A - 80 A

Length x width

2.5m x 2.1m

Total weight

5'800 kg

Table / slide Z-axis

Travel range

450 mm

Feed rate Speed

20 000 mm/min

Scale resolution

0.0025 µm

Cross slide X-axis

Travel range

450 mm

Feed rate Speed

20'000 mm/min

Scale resolution

0.0025 µm

Turned parts B1

Swivel range

330 degrees

Swivel speed

30 1/min

Automatic indexing Resolution

n/a

Encoder resolution

n/a

Turned parts B2

Swivel range

225 degrees

Swivel speed

30 1/min

Automatic indexing Resolution

n/a

Encoder resolution

n/a

Grinding head

Type

Revolver

External grinding

Power Peripheral speed

50 m/s

Drive motor Water-cooled

8 kW

Grinding wheel dimensions

Ø 300 x 40 mm

Internal grinding

Bore of the holder

Ø 120 mm

max. power HF spindles

15 kW

Max. rotational speeds

120'000 min-1

Workpiece headstock

Type

Standard 100 / Direkt 50 / Direkt 200

Speed range

1- 1000 / 3 000 / 1000 min-1

Encoder resolution

0.0001 degrees

Roundness accuracy for fly grinding

0.4 / 0.2 μm

External short taper ISO 702-1

Gr. 5 / Gr. 5

Mounting cone

MK5 / n/a / Mk5

Precision adjustment

± 1.5"

Tailstock

Mounting cone

n/a

Stroke

n/a

Precision adjustment

n/a

CNC control

Manufacturer / Type

Fanuc 0i-F

Machine operation

HMI

BLUE Solution

Software modules

Tool management

Standard

Global dresser

Standard

Global calibration

Standard

Tool type Cup wheel

Standard

Tool correction

Standard

AppOutOfRound (CAPTO)

Option

gSHAPE (with DXF import)

Option

Measurement of tool holder with gSET

Standard

Out of round grinding

Option

Jig grinding

Option

Product competence

Request

I am interested in a KELLENBERGER machine