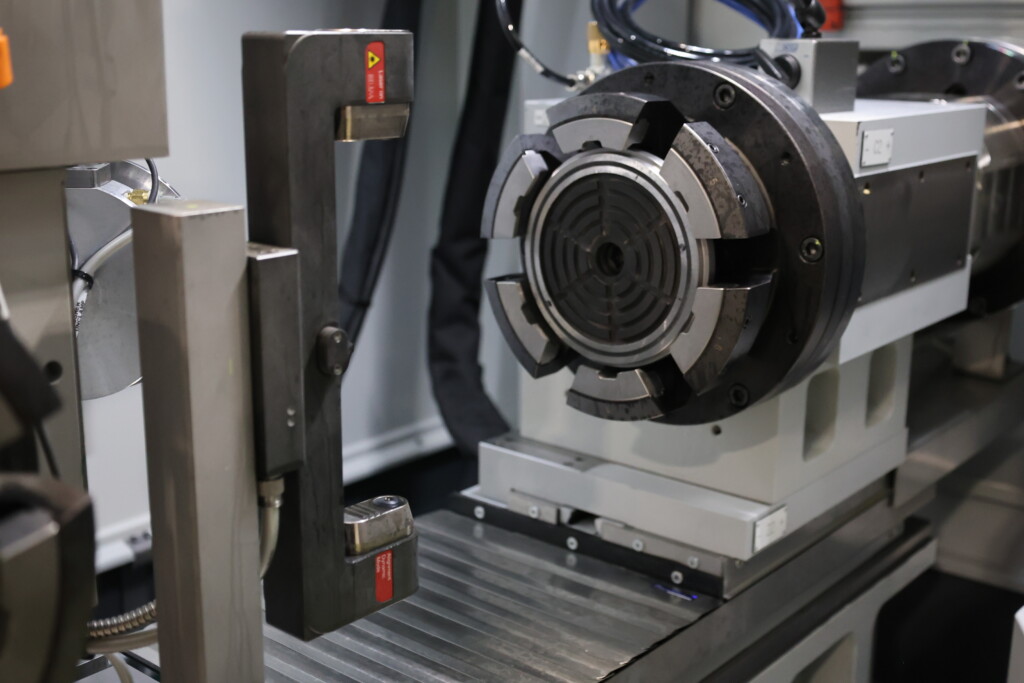

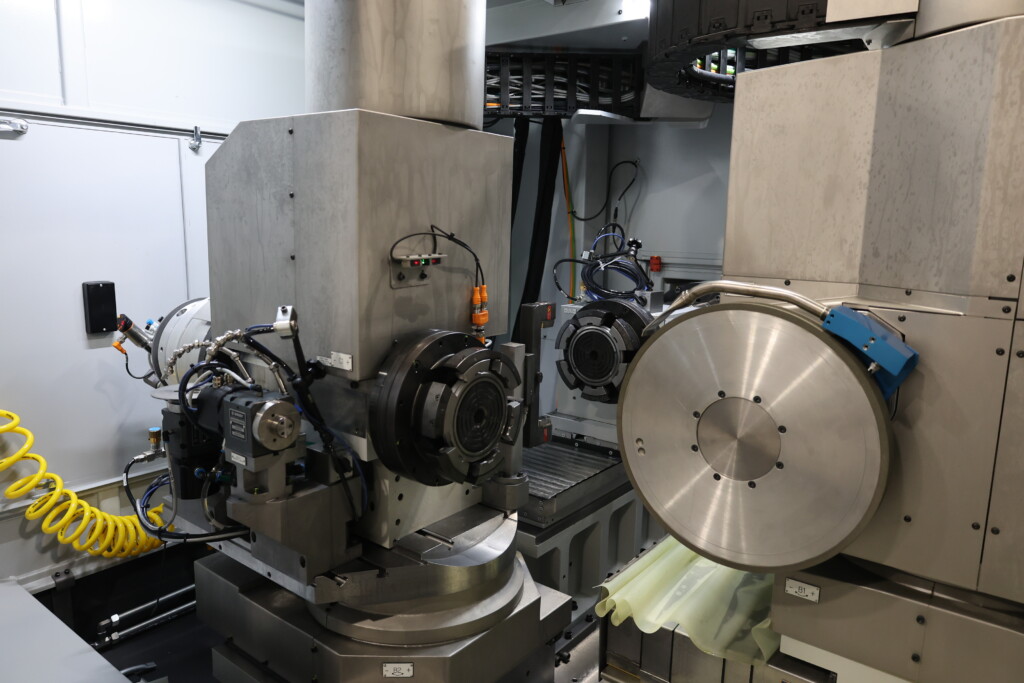

USACH BOULEPRO 200AX

Improved parts speed

Good Price-Performance ratio

Reduced production footprint

More accurately oriented parts

THE FUTURE OF SEMICONDUCTOR MANUFACTURING HAS BEGUN

Currently the only machine of its kind, the BOULEPRO 200AX enables much faster and more cost-effective conversion of boules into pucks to meet the high demand for silicon carbide (SiC), an important semiconductor material. With its SSDC (Single-Step Dual-Plane Compensation) capability, the BOULEPRO 200AX turns a traditionally multi-step process performed on multiple machines into a single-machine process that dramatically improves efficiency and costs at each step.

SOLUTION ADVANTAGES

- Improved part speed

- Reduced labour input

- Less space required in production

- Excellent process repeatability

- Reduction in required consumables

- Up to 500 times more accurate angular orientation

SIC MARKET AND END APPLICATIONS

- Silicon carbide is a semiconducting or semi-insulating material used in many different types of electronic devices such as diodes, MOSFETS, JFETS, etc. It replaces silicon-based devices for applications that require high power density, high frequencies and high voltages.

Electric vehicles (EVs) and 5G are major users of this type of component. - Silicon carbide is traditionally grown by physical vapour transport (PVT) in high-temperature furnaces, and it takes 2 to 4 weeks to grow a crystal (boule) of just a few kilograms in size.

The crystal must then be machined into a wafer-ready puck and then cut into wafers on which component manufacturers can build. - Kellenberger has developed an innovative solution for this post-growth processing step, in which a wafer-ready puck is created from the grown boule

TECHNICAL DATA BOULEPRO 200AX

Key data

Dimensions

220” x 169” x 130” (5600 x 4300 x 3300 mm)

Weight, approximate (in basic configuration)

25,000 lbs. (11,363 kg)

Required power, approximate

72A

Machine Axis

X-axis travel

23.62 '' (600 mm)

Y-axis travel

7.87 '' (200 mm)

Z-axis travel

19.68” (500 mm)

Z2-axis travel

9.8” (250 mm)

X, Y and Z-axis feed rate

0 - 787'' / minute (0-20 m / minute)

Axis resolution (all linear axes)

.000004” (.1 micron)

Axis resolution B1 and B2

0.00002 deg

Request

I am interested in a machine