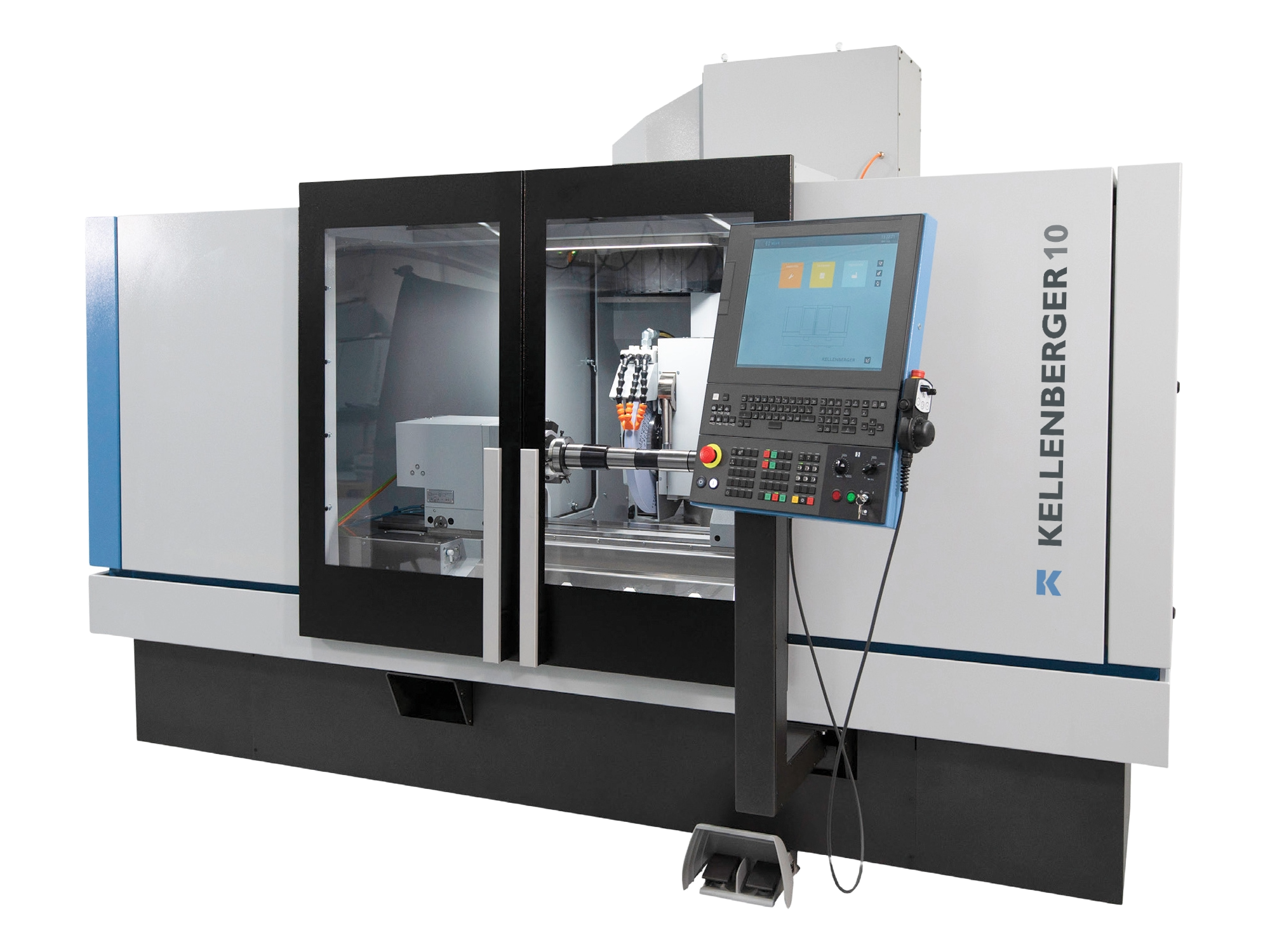

The universal cylindrical grinding machine KELLENBERGER 10 is a cost- and cycle-time-optimized, energy-efficient standard machine that stands out with its excellent price-performance ratio. It offers high availability, process reliability, and consistent performance. At the same time, it ensures productivity, flexibility, and easy retooling. With a center height of 200 mm, a center width of 1,000 mm, and generous axis strokes of 365 mm (X-axis) and 1,150 mm (Z-axis), the machine accommodates a wide range of workpieces weighing up to 100 kg.

Advanced Technical Features

A key highlight of the machine is the automatic 1° indexing axis, which ensures high positioning accuracy. Additionally, it is equipped with a grinding head featuring two external grinding wheels, each with a diameter of 500 mm, providing flexibility with primary and secondary wheels. The direct-drive internal grinding spindles achieve speeds of up to 60,000 rpm, enhancing the machine’s efficiency for complex grinding tasks.

Extensive Retrofit Options

Thanks to its modular design, the KELLENBERGER 10 can be customized with various options. Available upgrades include a tailstock, active longitudinal positioning, as well as lead-in and balancing sensors. Extended dressing options are also available, making the machine adaptable to a variety of manufacturing requirements.

User-Friendly Operation and Quick Commissioning

The KELLENBERGER 10 is equipped with the cost-optimized FANUC 0i-F Plus control system. Its 19-inch touchscreen and innovative BLUE Solution software enable intuitive programming, even for inexperienced operators. Additionally, the hook machine design ensures fast and efficient commissioning, reducing setup times significantly.