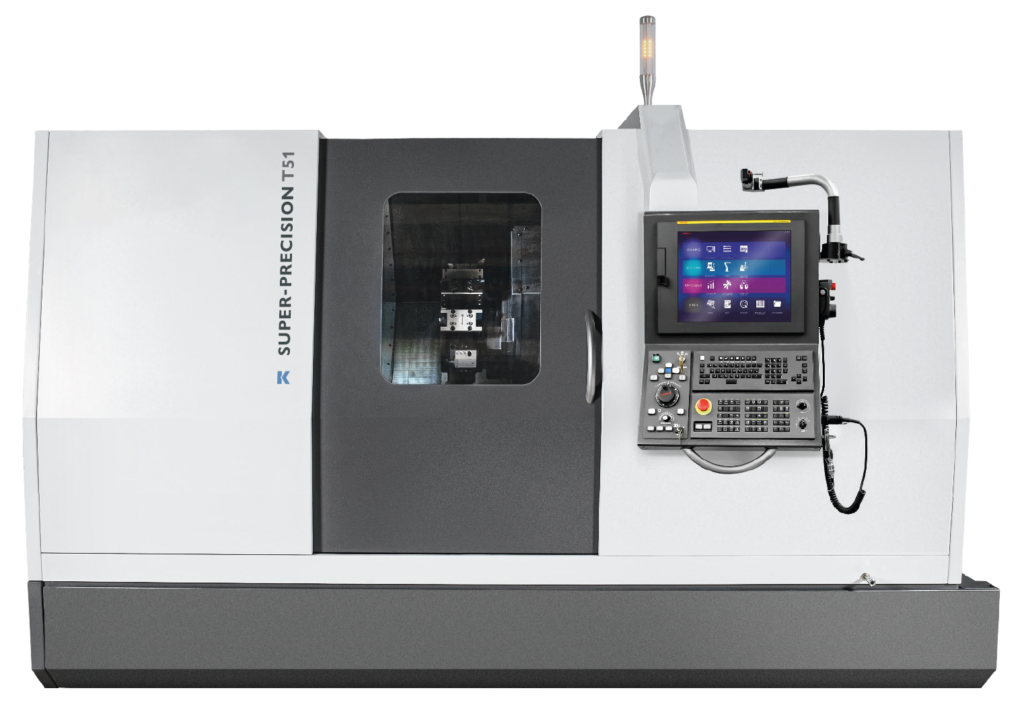

SUPER-PRECISION T-SERIES

High surface quality of 0.2μ or better

High Machine rigidity qualified by fea technology (fine element analysis)

Dynamic balancing of spindle and drive motor

The undisputed market leader in SUPER-PRECISION® for the most demanding jobs

SUPER-PRECISION T-Series turning centers set the standard for high-precision, high-performance turning that makes unprecedented part quality and production capacity a reality. Designed to exceed your expectations, SUPER-PRECISION T-Series machines are ideal for high-precision two-axis machining or complex multi-tasking operations that require a high degree of precision and delicate part handling, as well as parts that are completely machined in a single setup. The machine packages are pre-configured with our most popular features, so you can choose the right machine tool configuration to produce your parts in the most effective and profitable way.

FEATURES AND OPTIONS

SUPER-PRECISION is a combination of best practices, design and manufacturing hardware and software integrated into a machine tool that provides the highest level of precision for production turning centers that require the least human intervention on the market today.

Key differentiators

- High machine rigidity qualified by FEA (Finite Element Analysis) technology

- High surface quality of 0.2 μ or better

- Circularity test for maximum geometric accuracy

- Dynamic balancing of spindle and drive motor

- Integrated wrap-around spindle motor technology without the use of belts

- Matched high-precision spindle bearings

- Ability to maintain total diameter deviation within 3 μ after a short warm-up time

- High repeatability of the axes of 0.76 μ

- Robust control / motor / drive package with 0.1 μ control resolution

- High-precision digital linear glass scales

CONTROL UND SOFTWARE

FANUC 31i TB – Control functions obtained

- Tool offset with geometry / wear (99) (XYZR)

- Inch / Metric selection according to G-code

- Memory extension 64 Kbyte (160 meters)

- Absolute / incremental programming

- Alarm display

- Setting the automatic coordinate system

- Background processing

- Skip block

- Fixed cycle (turning / drilling)

- Chamfer / corner radius

- Circle interpolation through R programming

- Programming the constant cutting speed

- Continuous thread cutting

- Setting the coordinate system (G50)

- User-defined macro B

- Decimal point programming

- Diameter / radius programming

- Programming with direct drawing dimensioning

- Display position, program, alarm history

- Ethernet capable

- Advanced part program editing (copy / replace)

- External workpiece number search

- Flexible reference run

- Helical interpolation (all M S models)

- Help screen

- Input of correction values (G10)

- Interpolation (linear/circular)

- Test run

- Manual Guide i with full color display

- Program number search

- Input of programmable parameters

- Moving to the reference point

- Program management (1000)

- Thread cutting without compensating chuck – all spindles

- Workpiece counter

- Self-diagnosis function

- Spindle orientation (1 degree)

- Spindle synchronization (all S models)

- Sequence number search

- Single block operation

- Skip function G31

- Travel check 2 & 3

- Straightness compensation

- Sub program call (10-fold nested)

- Accuracy compensation

- Tool nose radius compensation

MAIN FEATURES

Advantages of the collet chuck spindle

Collet chuck sits directly in the Hardinge spindle

Maximum rigidity and clamping force are transferred to the part

Maximum utilization of the speed

Minimal weight on the spindle

Minimal overhang from the spindle bearings, which ensures that the spindle accuracy is transferred directly to the workpiece

Optimum T.I.R.

Clamping force directly above the workpiece

Excellent tolerances and surface finishes

Utilization of the maximum machining capacity of the machine possible

Longer tool life

Fast retooling

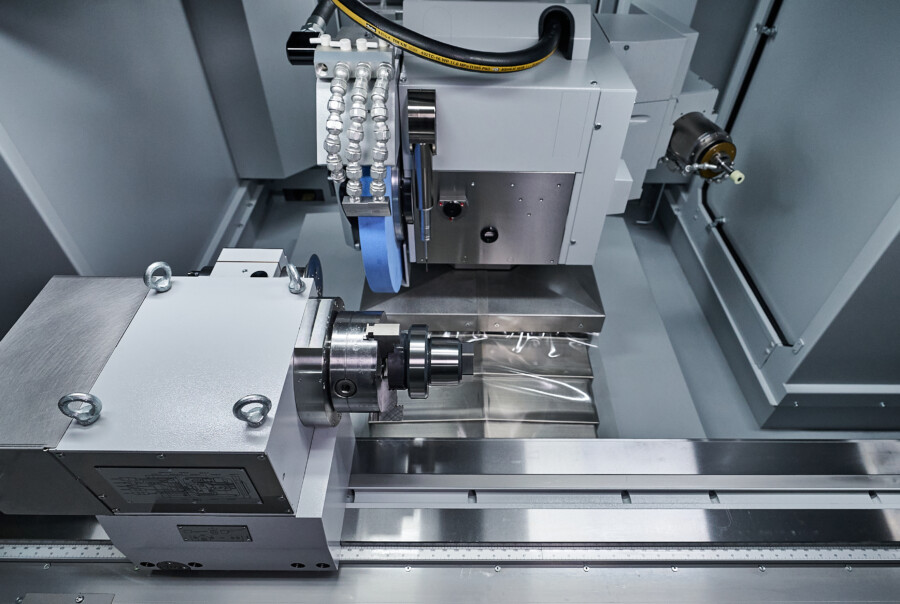

Driven tools

Driven toolholders start at 8,000 rpm and are optionally available with a 2:1 or 4:1 ratio up to 32,000 rpm when high speeds are required. Hardinge’s BMT driven toolholders offer excellent concentricity within 3 μ, making them one of the best tooling systems in the industry.

Technical Data

T-42

T-51

T-65

Spindle HP

15 HP (11 kW)(30 min.)

20 HP (15 kW)(Continuous)

35 HP (26 kW)(Continuous)

Spindle Speed

6,000 RPM

5,000 RPM

4,000 RPM

Chuck Size

6" (150 mm)

8" (200 mm)

10" (250 mm)

Max. Machining Length

14.2" (360.7 mm)

23.6" (599.5 mm)

23.6" (599.5 mm)

Max. Machining Diameter

8.91" (226.3 mm)

12.35" (313.7 mm)

12.35" (313.7 mm)

Bar Size

1.625" (42 mm)

2" (51 mm)

2.5" (65 mm)

No. Turret Stations

16 Station (BMT-45)

12 Station (BMT-55)

12 Station (BMT-55)

CNC Control Unit

FANUC 31i

FANUC 31i

FANUC 31i

Approx. Machine Weight

13,100 lbs (5,940 kg)

17,200 lbs (7,800 kg)

17,200 lbs (7,800 kg)

Floor Space

98" x 83.5" x 82.25" (2,489 mm x 2,121 mm x 2,089 mm)

128.23" x 91.04" x 83.6" (3,257 mm x 2,312 mm x 2,123 mm)

128.23" x 91.04" x 83.6" (3,257 mm x 2,312 mm x 2,123 mm)

PRODUCT COMPETENCE

Request

I am interested in a machine