With the BLUE Solution touch HMI control software, Kellenberger has developed an innovative operating philosophy for all KELLENBERGER and VOUMARD series.

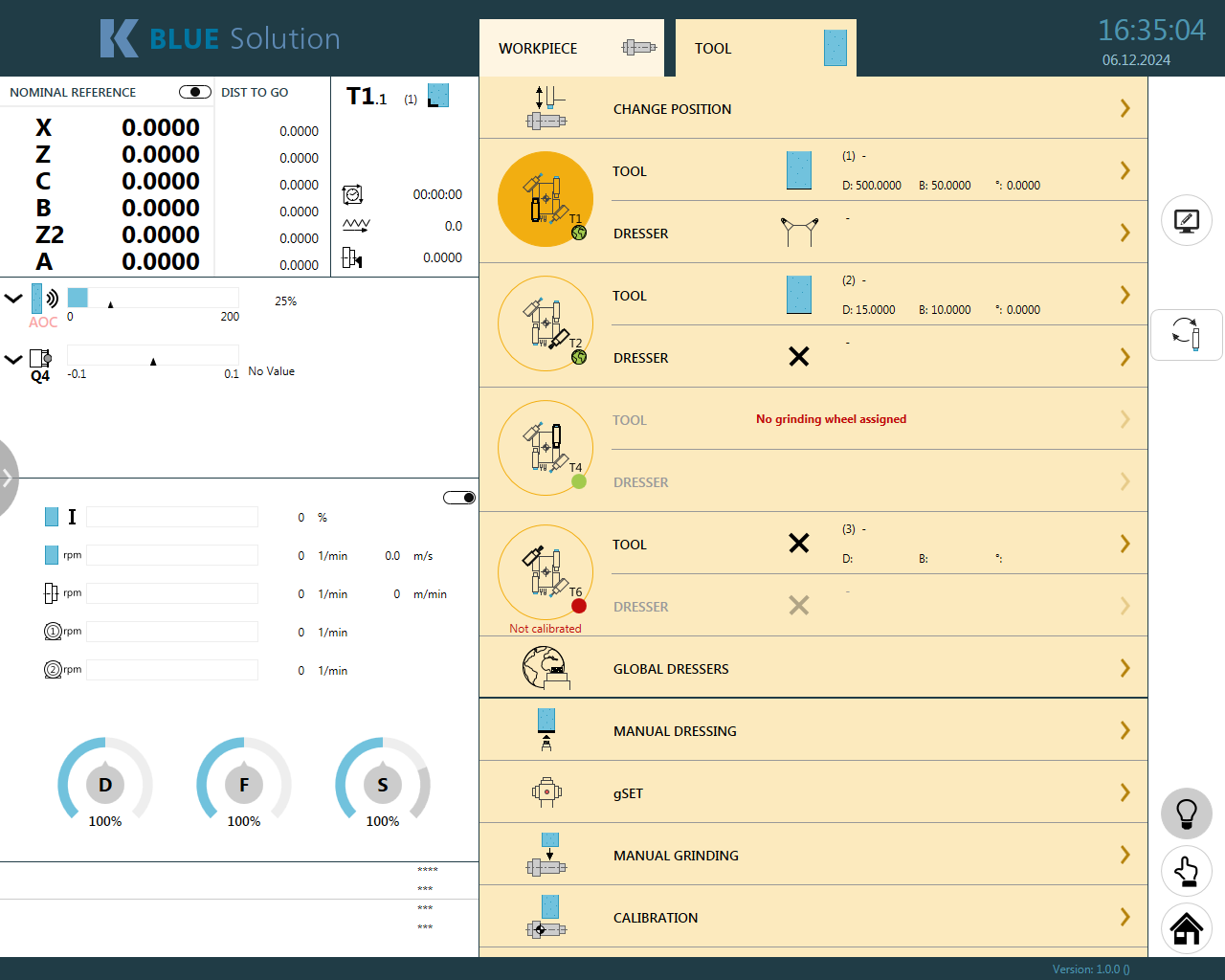

Regardless of whether the focus of processing is internal grinding or external grinding. The BLUE Solution uses a completely new software architecture that is designed for touch operation with all familiar gestures.

When entering data, the operator is given maximum support by an intelligent control system. This system is equipped with plausibility monitoring, which reports incorrect entries at an early stage.

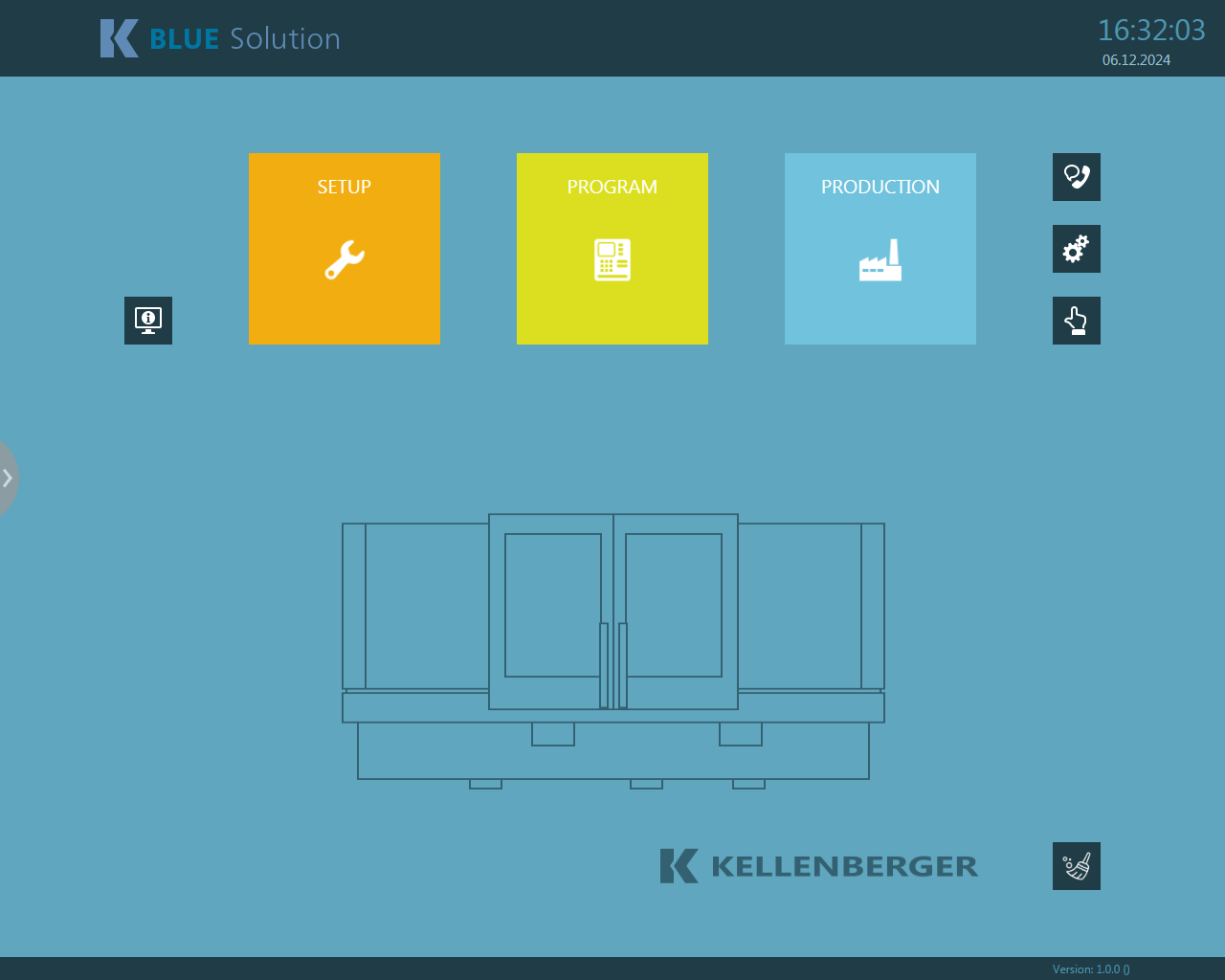

The clear division into the three main areas of set-up, programming and production as well as the three secondary areas of diagnostics, settings and functions makes setting up a machine for a new production process easier than ever.

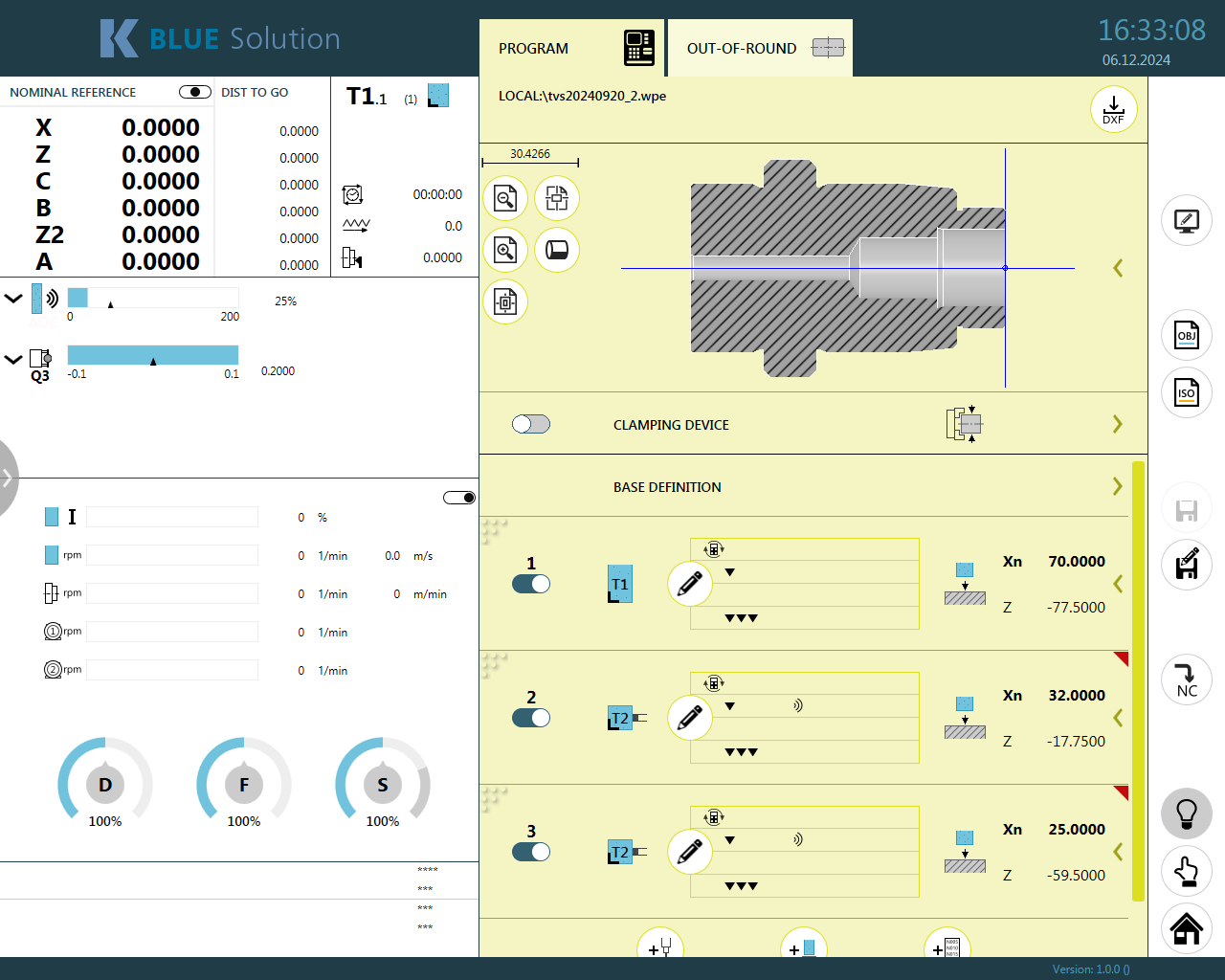

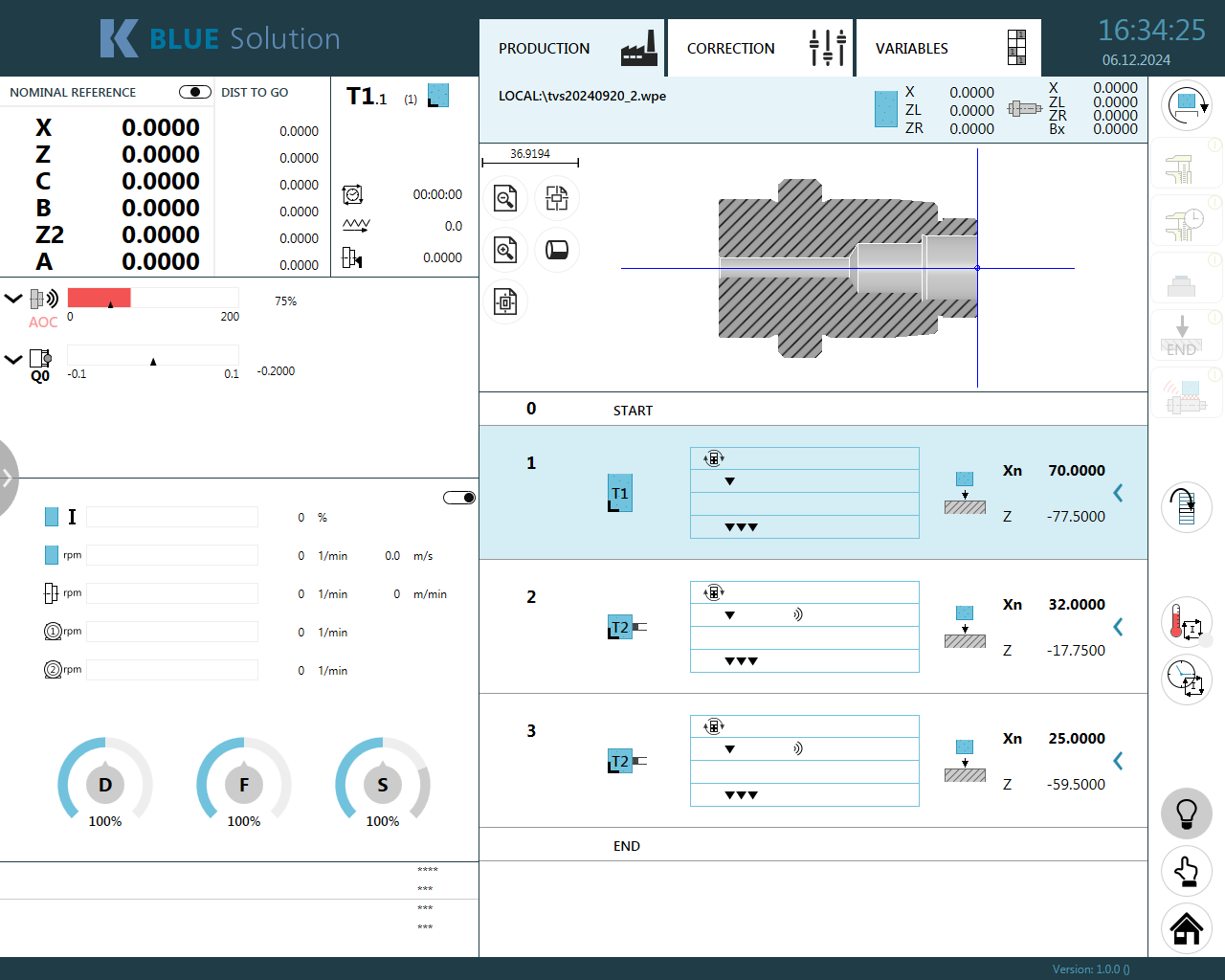

Even complex grinding programs can be created in the BLUE Solution without the need for ISO code knowledge. This significantly reduces the entry hurdles for users and ensures fast and efficient implementation of demanding sanding tasks.

Workpiece information can be imported directly from CAD data into the BLUE Solution. Based on the contour information of the workpiece, the software automatically determines collision-free grinding positions and the optimum technology data for grinding and dressing. This allows a complete grinding program to be created – even without in-depth knowledge of grinding technology.

Available on the series: