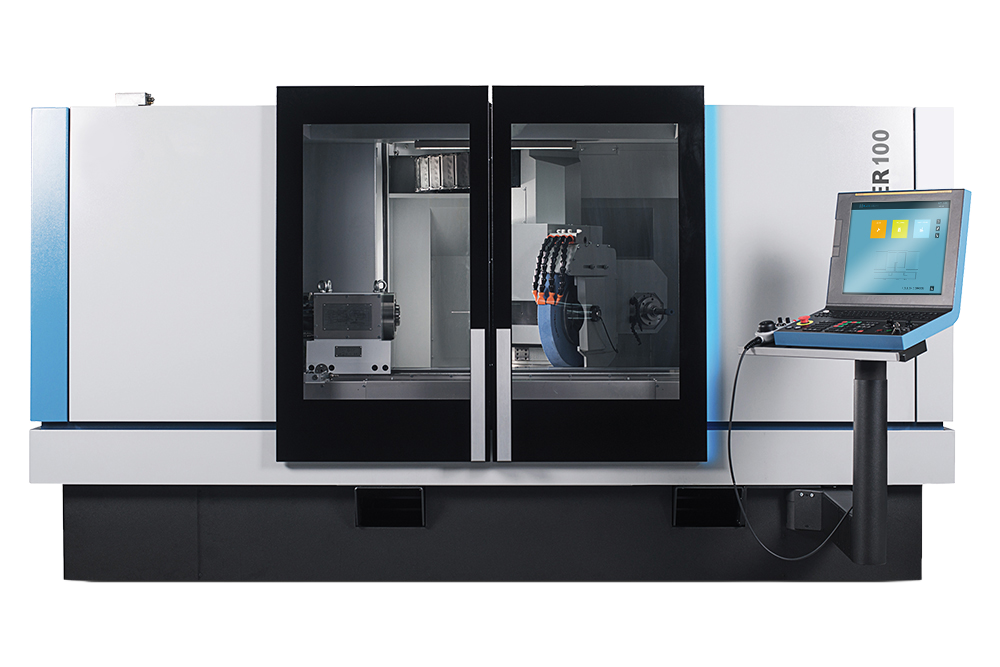

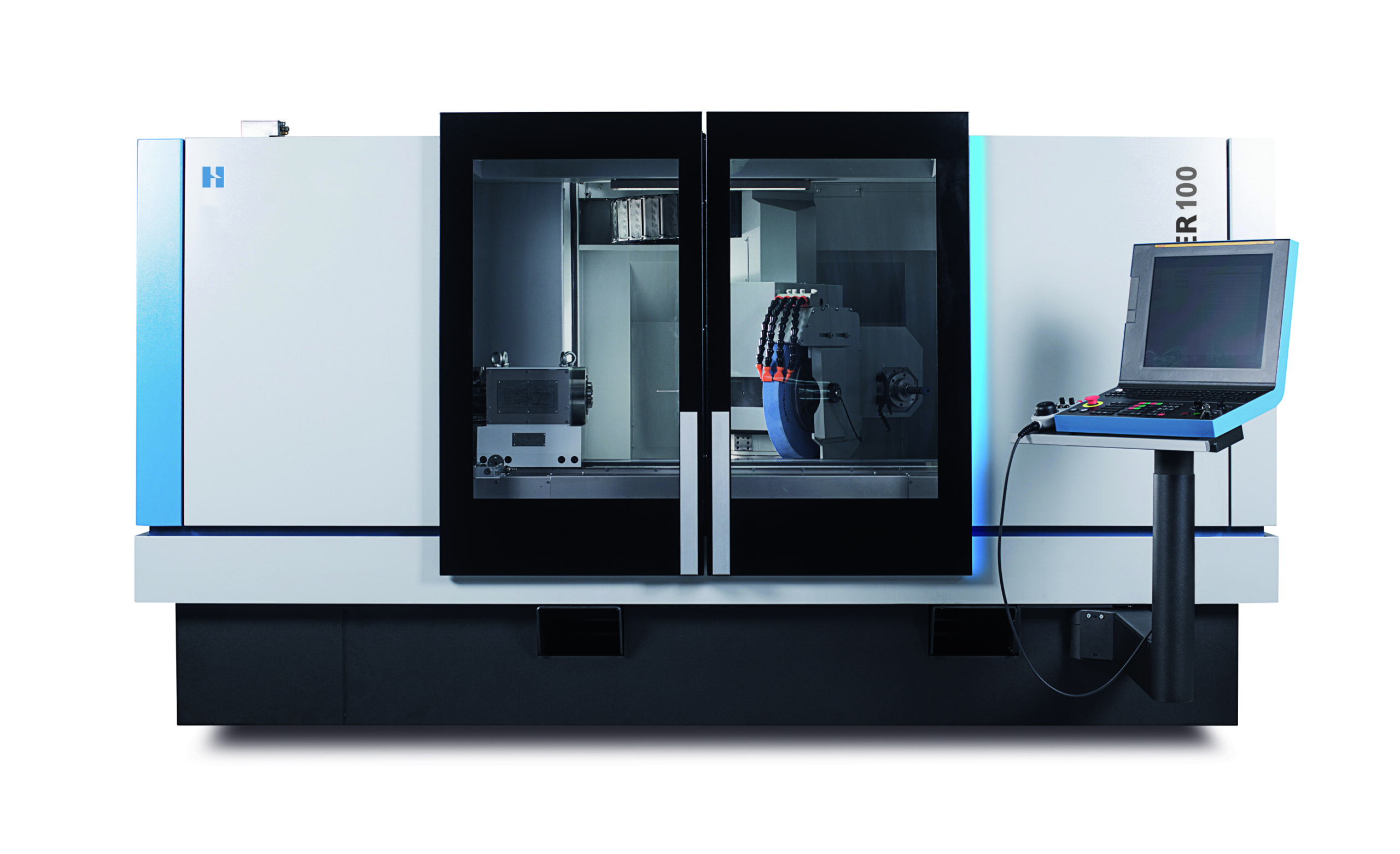

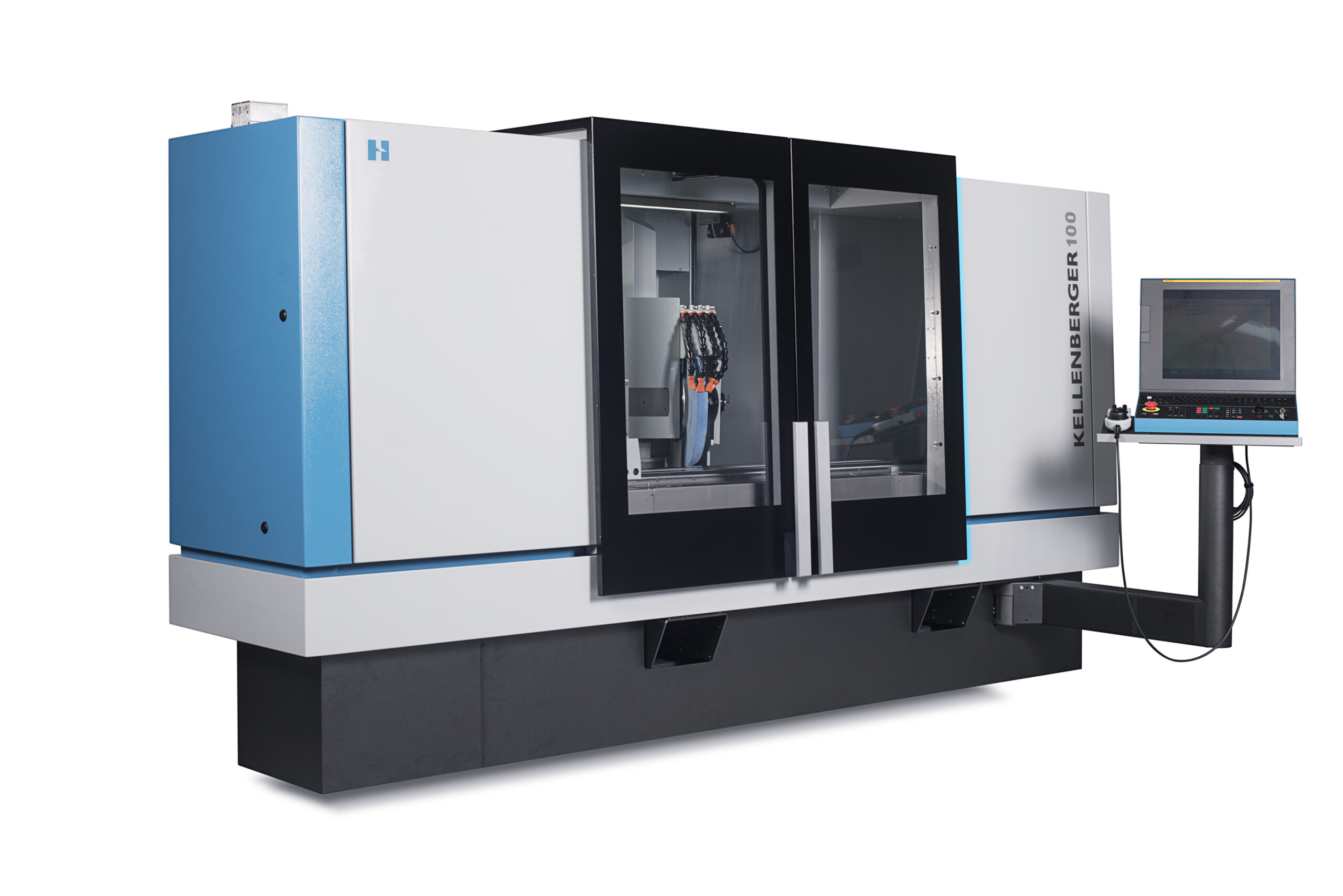

The universal cylindrical grinding machine KELLENBERGER 100 offers many configuration options, making it ideal for various grinding operations and enabling strong customer focus. Thanks to its versatility, this machine is designed to meet a wide range of precision grinding needs across industries.

Exceptional Versatility for Various Applications

With a center height of 200 / 250 mm and center widths of 600/1’000 / 1’700 mm, the KELLENBERGER 100 can handle a diverse range of workpieces. Moreover, its X-axis strokes of 370 mm and Z-axis strokes of 750/1,150 mm expand its application possibilities. The machine processes workpieces weighing up to 200 kg, making it suitable for many industrial tasks. Additionally, the CNC-controlled B-axis with direct drive ensures high positioning accuracy, while direct-drive internal grinding spindles reach speeds of up to 90,000 rpm. These features collectively enhance the machine’s flexibility and precision.

High Productivity and Accuracy

The large grinding wheel drive power significantly boosts productivity, ensuring consistent performance even under demanding conditions. Furthermore, the new Z-guide plays a crucial role in improving profile accuracy. For non-circular grinding tasks, the C-axis with direct drive ensures even greater precision, making the KELLENBERGER 100 a reliable choice for challenging operations.

Technical Highlights of the KELLENBERGER 100

Key features include a compact grinding head with 10 variants, offering 11.5 kW drive power and a 500 mm grinding wheel with speeds of up to 63 m/s. Moreover, the machine includes a collision-free universal head with three tool positions and one measuring position. The newly designed measuring probe arrangement eliminates the swivel mechanism, thereby improving measuring accuracy. In addition, the synchronous tailstock allows for complete machining of shafts without a driver, enabling workpieces to be fully processed over their entire length.

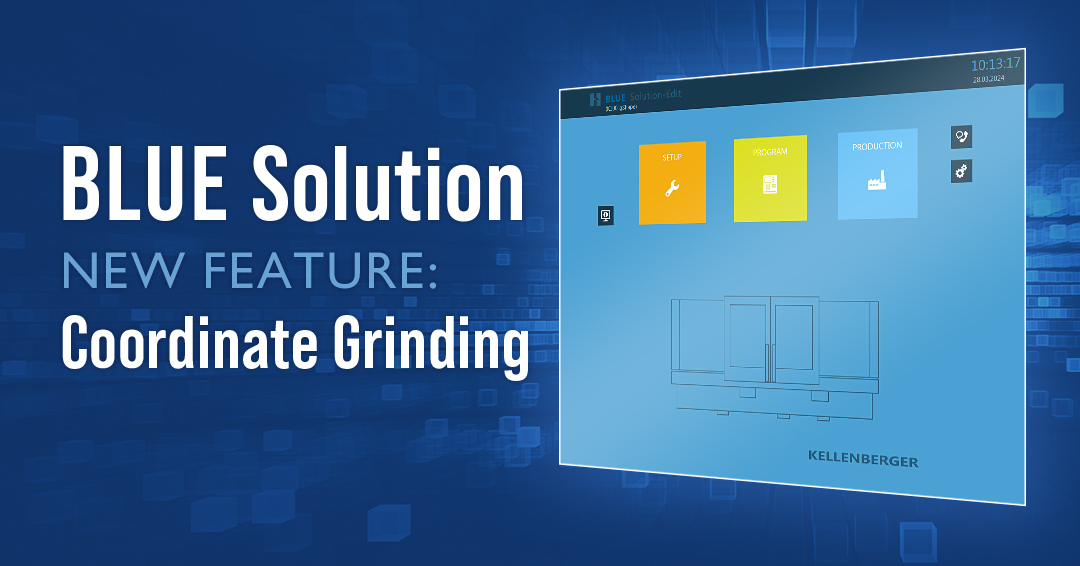

User-Friendly Design and Advanced Technology

The reinforced casing supports larger grinding wheel diameters for internal grinding, enhancing the machine’s overall performance. Meanwhile, operator guidance is simplified through an intuitive 19″ touchscreen interface powered by the FANUC 31i-B CNC control system. Finally, the innovative BLUE Solution software ensures even inexperienced operators can quickly and intuitively program grinding tasks, making operations both efficient and user-friendly.

By combining advanced technology, flexibility, and user-centric design, the KELLENBERGER 100 universal cylindrical grinding machine delivers exceptional performance tailored to meet diverse industrial needs.