Kellenberger und Weisser at AMB

Flexible machine concepts and innovative processes

At the AMB fair in Stuttgart, Germany, lathe manufacturer Weisser will be showcasing the newly developed non-circular turning unit HOT V4, which facilitates non-circular turning of parts with difficult workpiece geometries. The non-circular shapes are produced by interpolating the workpiece spindle axis with the infeed axis of the tool that generates the diameter. The radial, oscillating movement of the tool cutting edge (8 mm stroke) is generated with a highly dynamic oscillation drive. An acceleration of 300 m/s2 is achieved at maximum feed speed. Thanks to the reinforced HOT V4 unit and the variable cutting edge arrangement, free-form surfaces can now be produced by turning the lateral and end faces.

Polygonal shapes (shaft-hub connections) ensure extremely stable connections

The highly dynamic drive provides an increase in performance capacity of up to 300% and makes turning non-rotationally symmetrical parts more economical than milling, especially in high-volume production. At the same time, a first-class surface finish is generated.

The module developed and patented by Weisser can be integrated into any UNIVERTOR machine for non-circular turning, including the UNIVERTOR V400 presented at the trade fair, which covers a wide range of applications in the medium and large-scale production of workpieces in all materials such as cast iron, aluminum, steel or titanium. With two powerful disk turrets (four axes), the UNIVERTOR V400 enables highly productive simultaneous machining. Working with two tools at the same time shortens the machining time and thus reduces unit costs.

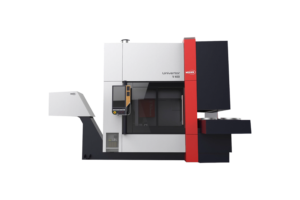

Weisser UNIVERTOR V400

The modular design allows a variety of processes such as non-circular turning, rotary turning, hard turning, internal and external cylindrical grinding and gear cutting with the best surface quality on workpieces such as brake discs, differential housings, stator housings and axle drive wheels. The machine is equipped with automation with a drag frame belt as standard. Other automation solutions can be easily adapted via the integrated interface.

Integration of processes: MultiCenter MTS 1200/8

Weisser will also be exhibiting the MultiCenter MTS 1200/8 horizontal 5-axis machining center at AMB, which was developed for the complete machining of highly complex and precise workpieces typical for mechanical engineering, electromobility, medical technology and aerospace industries.

The machine offers maximum process reliability and is characterized by high vibration damping, flexibility and precision. The solidly designed basic mechanics in combination with 55 mm guideways guarantee the best performance for demanding applications in hard and soft machining. In addition to classic turning, milling and drilling, the MultiCenter MTS 1200/8 integrates the process technologies of rotary turning, skiving, hobbing and whirling.

WEISSER MultiCenter MTS 1200/8 with integrated automation

Weisser Präzisionstechnik presents premium laser welding systems

The fully automatic laser welding system HLA-M+ opens up limitless processing possibilities in medical technology with its cross table, rotary swivel unit and joystick

At the Weisser company headquarters in St. Georgen, Germany, manual, semi-automatic and fully automatic laser welding systems are built under the “Weisser Präzisionstechnik” label, primarily for the medical technology sector. The modular WEISSER HLA systems are available in three versions, two of which can be individually configured, so that the right system is available for every application. The semi-automatic and fully automatic HAL-M and HAL-M+ expansion stages allow a wide range of processing options with retrofittable components such as a cross table or rotary swivel unit. The beam source used in every HLA system is a high-quality Trumpf laser, which is one of the best on the market. Weisser Präzisionstechnik will be exhibiting the fully automatic HAL-M+ laser welding system at the AMB.

KELLENBERGER 10: Process reliability and high availability

With the KELLENBERGER 10 universal cylindrical grinding machine, Kellenberger is presenting a standard machine that can be customized with a wide range of options and offers excellent value for money. With a center height of 200 mm, center width of 1,000 mm and generous X and Z axis strokes of 365 mm and 1,150 mm, the machine covers a wide range of workpieces weighing up to 100 kg. The machine is characterized by high availability, process safety, reliability, productivity and flexibility, as well as easy work-piece set-up.

The low-maintenance, high-precision linear guide in the X-axis and the V-flat sliding guides in the Z-axis are equipped with linear path measuring systems. The B-axis is designed as an automatic indexing axis (1° Hirth serration) with high positioning accuracy and +30°/-210° swivel range. For high productivity and flexibility, the universal grinding head can optionally be equipped with two external grinding wheels with diameters 500/400 mm. Powerful grease-lubricated high-frequency internal grinding spindles with direct drive are available in two speed ranges 4,000-40,000 rpm and 6,000-60,000 rpm. The KELLENBERGER 10 is equipped with the cost-optimized FANUC 0i-F Plus control with 19” touch screen and the innovative BLUE Solution software, which enables even inexperienced operators to program quickly and intuitively.