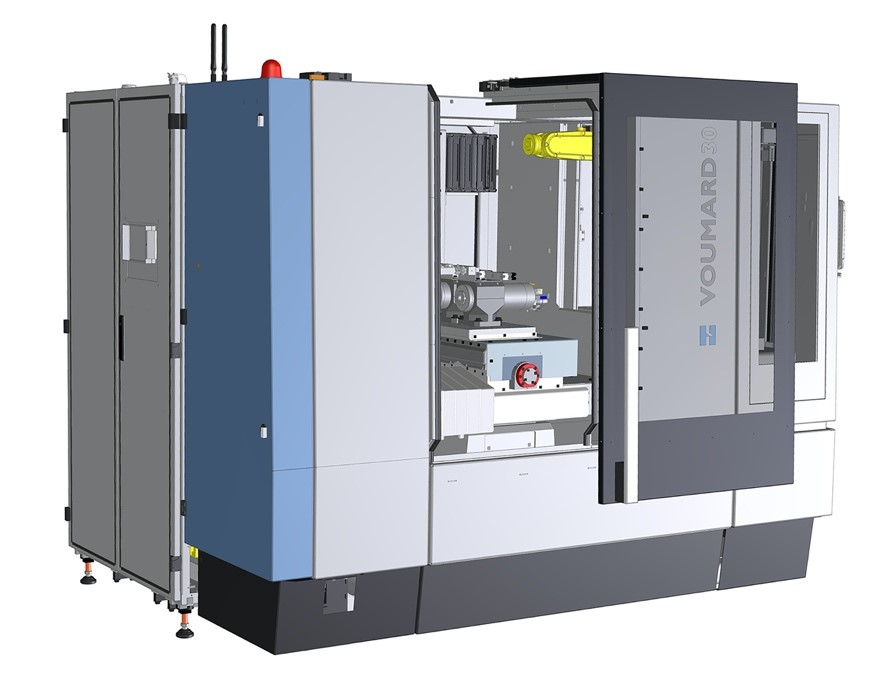

The VOUMARD 30 internal grinding machine, which was lauched in 2023, complements the high-precision internal grinding expertise of the Voumard brand with a machine for all industries whose main focus is on simple internal grinding operations in small and medium series. The VOUMARD 30 is designed for workpieces up to 150 mm in length and 150 mm in diameter. High-quality internal grinding spindles ensure the best grinding results with short cycle times. They are available with speeds from 45,000 to 120,000 rpm. Other outstanding features include the high-precision workhead and a high-precision X/Z cross table. With a footprint of 1.80 x 1.80 metres, the VOUMARD 30 is particularly suitable for small and medium-sized companies. With its excellent price/performance ratio, it is also an ideal entry-level machine.

Kellenberger has now developed the REX robot cell, a tailored automation for the VOUMARD 30 with a very small footprint. Product Manager Patrick Zünd played a key role in realising this integrated automation: “Grinding was always the last process in production to be automated. Today, more than 25% of all enquiries are machines with automation. In the case of smaller standard machines, automation is often already included in the machine design.”

Compact machine, compact automation. The footprint of the of the VOUMARD 30 with robot cell is just 2.30 x 1.80 m

The REX automation system was specially designed for the VOUMARD 30 and structurally anchored in the machine. It is very compact and increases the footprint of the VOUMARD 30 by just 500 mm in width. The loader is integrated into the machine panelling, but forms a separate mechanical unit. The double gripper (raw/finished part gripper) for inner diameters from 14.5 mm and outer diameters from 4.5 mm has gripper jaws with grid option and a blow-off nozzle.

The machining area is separated from the automation system by a lockable loading hatch, which is open during workpiece changeover. The pallets are changed manually via a side door. To load and unload the pallet (pallet size: 400 x 600 mm), it is pulled out of the enclosure using a device.

The REX loader automates the VOUMARD 30 without taking up much space. The loading access to the machine room is closed during processing.

The REX automation system is designed for chuck components < with a maximum weight of 2 kg. The workpiece changeover time is approx. 12 s without clamping time. The Rex loader has its own control system with set-up assistant for quick changeover to a new workpiece. In addition to the universal loaders, many other automation solutions are available in the Kellenberger portfolio. The design department at Kellenberger develops customised solutions for special requirements.