Automation has long been a major topic in any production, as it allows entire shifts to be operated unmanned or enables multi-machine operation during normal shifts. The Swiss grinding specialist Kellenberger has been continuously working on automation solutions that are optimally adapted to the KELLENBERGER 100 and 1000 series as well as for the VOUMARD 1000 and significantly increase flexibility in production for customers. Standard solutions are optimally supplemented by customized automation.

The product specialists at Kellenberger have now significantly expanded the available product portfolio by developing the universal pallet loader solutions FLY and STEP, both of which supplement the FLEX loader line, which has already proven itself on the market.

FLY – the universal loader for starting automation

In the basic segment, the FLY universal loader with its compact, modular design offers the ideal entry into machine automation. The FLY loader is designed for shaft parts up to Ø 70 mm, length up to 600 mm, as well as for chuck parts up to Ø 100 mm. With an overall size of 1,200 x 1,400 x 2,200 mm (L x W x H), the FLY is easy to integrate into any production environment. The FLY loader was designed for workpiece weights of max. 5 kg in alternating operation (length up to 280 mm) and 10 kg in single part operation.

The Kellenberger product specialist responsible, Patrick Zünd, co-developed the unique concept of the compact FLY series.

The pallet lift is designed for 5 pallets in the size 400 x 600 mm. The attractively priced basic version with 2 pallets can be extended up to 5 pallets at any time. The concept of the FLY series is so far unique on the market. The loader was specially developed for the KELLENBERGER 100 and is structurally anchored in the machine. Therefore, this solution cannot be retrofitted to existing machines.

STEP – the universal solution for all machine series

The loaders of the STEP series were developed for the KELLENBERGER 100 and 1000 as well as for the VOUMARD 1000. The STEP is designed for shaft parts up to Ø 100 mm, length up to 650 mm and max. gripping diameter 80 mm, as well as for chuck parts up to Ø max. 230 mm. The STEP loader was designed for workpiece weights of max. 5 kg in alternating operation (length up to 280 mm) and 15 kg in single part operation.

Five pallets with a size of 340 x 660 mm bring high autonomy in production. Interchangeable gripper heads facilitate quick changeover between shaft and chuck parts. The loader is equipped with a Siemens Simotion control with setup wizard for quick changeover to a new workpiece. The STEP loader can be retrofitted to all suitable machines.

Interchangeable gripper heads for quick changeover between shaft and chuck parts in the STEP and FLEX series

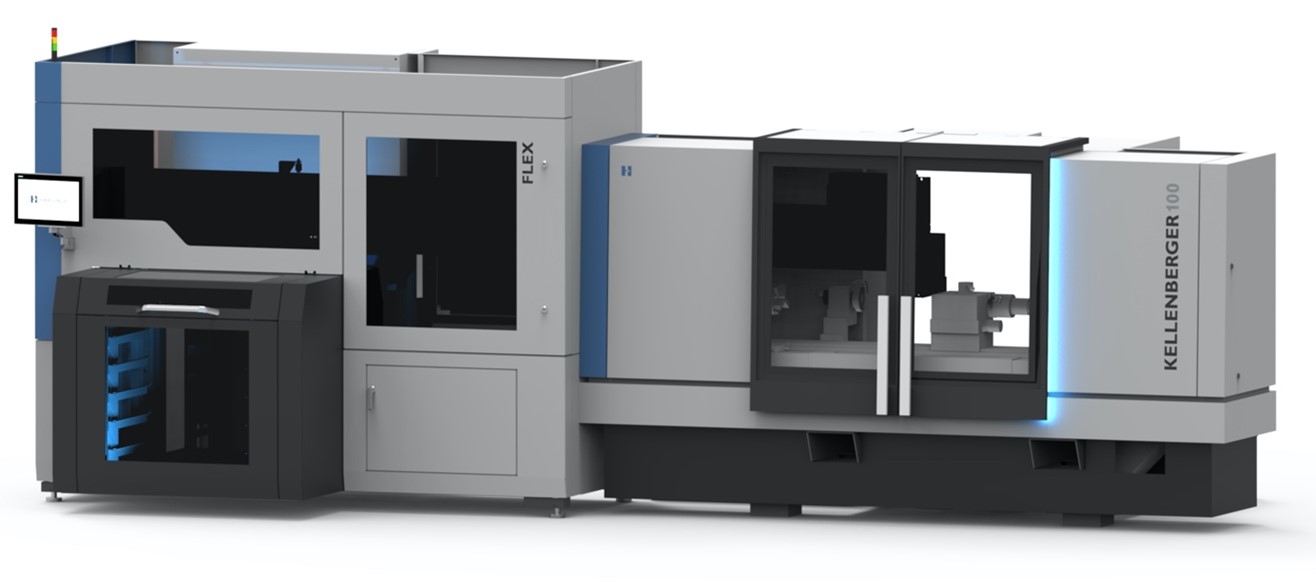

FLEX – the customizable pallet automation system

The FLEX loader for chuck and shaft parts increases the flexibility of the KELLENBERGER 100 and 1000 series, which offer a wide range of configuration options for the most diverse grinding operations. It enables automated processing of shaft parts up to Ø 100 mm, length up to 600 or 1000 mm (depending on machine version) and max. gripping diameter 80 mm, as well as chuck parts up to max. Ø 230 mm. The FLEX loader was designed for workpiece weights of max. 5 kg in alternating mode (length up to 280 mm) and 15 kg in single part mode.

The FLEX loader automates the KELLENBERGER 100 and 1000 series

In the stacking module, 10 pallet spaces of size 400 x 600 mm or 1000 mm (depending on machine version) are available. Devices for shaft or chuck parts can be inserted into the pallet frame. The machine is loaded via a telescopic line gantry. An automatic hatch closes off the machine room during machining to ensure the thermal stability of the machine. To reduce energy consumption, the speed of the FLEX is automatically adjusted to the cycle time of the processing machine. Like the STEP, the FLEX loader is equipped with a Siemens Simotion control with setup wizard for quick changeover to a new workpiece. The Flex loaders can be retrofitted to all suitable machines.

In addition to universal loaders, many other automation solutions are available in the Kellenberger portfolio. For special requirements, the Kellenberger specialists develop customer-specific solutions.