Innovative transfer of cylindrical grinding technologies

For the Swiss grinding specialist Kellenberger, the new production facility in Goldach has already proven its worth. The synergies that arise from merging all the Hardinge Group’s grinding brands form the basis for a ground-breaking technological innovation in the field of cylindrical grinding.

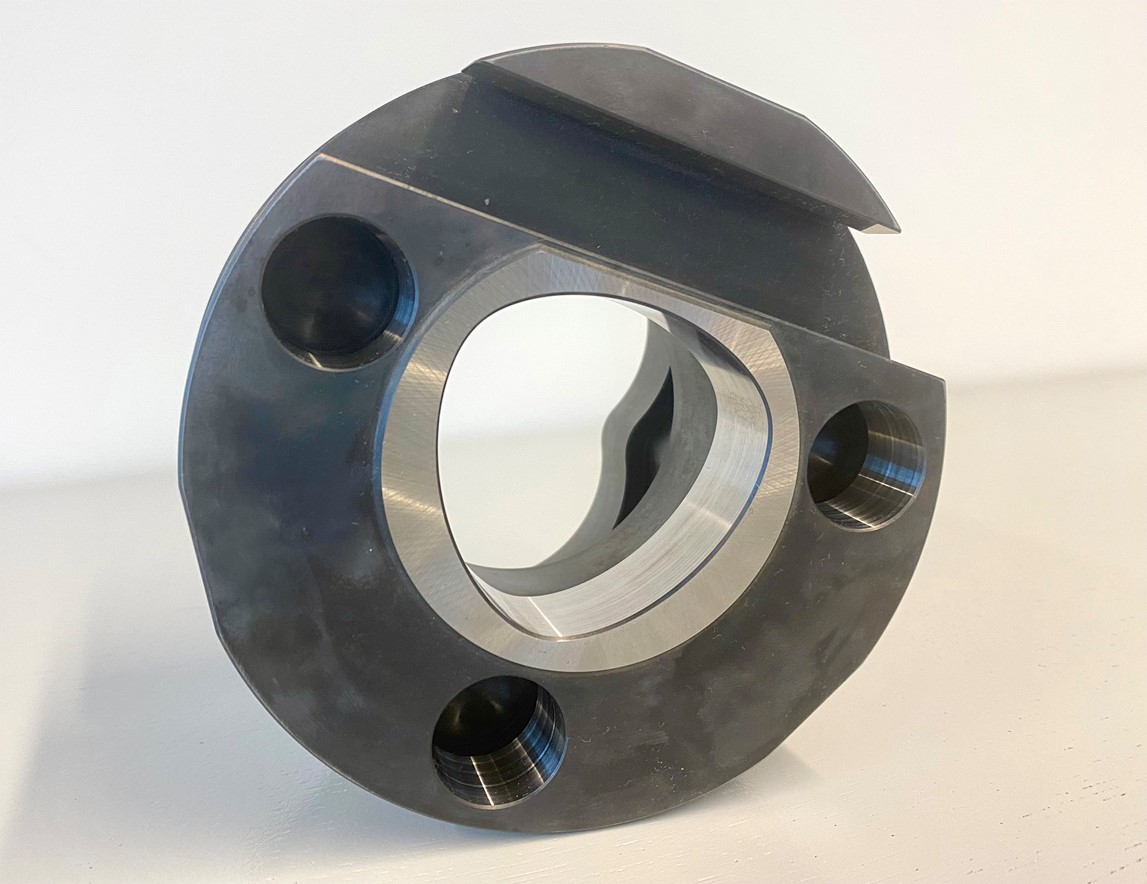

Workpiece example for jig grinding on Kellenberger and Voumard machines

The Hauser high-precision jig grinding machines provided the technology. The engineers and software experts at Kellenberger used their know-how for the integration of this technology into all Kellenberger and Voumard cylindrical grinding machines with a controlled C-axis. This means that it is now possible, for example, to also grind grooves and satellite bores during the grinding process chuck and spindle parts. With no reclamping necessary in this case, the high precision in the µm range is maintained.

New graphical mode „gSHAPE“ for importing dxf files

The “gSHAPE” graphical mode can import and process technical drawings directly in the BLUE Solution software.

The BLUE Solution software has also been innovatively enhanced. Drawings of a workpiece in dxf format can now be imported directly using the new “gSHAPE” extension. The target contour of the workpiece from the drawing is technologically enhanced in the OBJECT Guide of the BLUE Solution and translated into grinding processes, including the grinding wheel position. Drawing interpretation and transfer errors are eliminated. This new tool allows for a digital workflow from drawing to programming. The simple operation of the BLUE Solution is retained. The “gSHAPE” function is unique on the market.

VOUMARD 30 with automation and extended dressing options

The recently launched internal grinding machine VOUMARD 30 complements the high-precision internal grinding expertise of the Voumard brand with a machine for all industries whose main focus is on simple internal grinding operations in small and medium series.

The VOUMARD 30 is designed for workpiece lengths of up to 150 mm and diameters of up to 150 mm. Depending on the application, either one or two parallel internal grinding spindles can be installed. These high-quality internal grinding spindles ensure the best grinding results combined with short cycle times. They are available with speeds from 45,000 to 120,000 rpm.

Further outstanding features include the high-precision workhead and a high-precision X/Z cross table.

Compact and powerful: VOUMARD 30 for small and medium batch sizes

The dressing options on the VOUMARD 30 have now been significantly expanded. In addition to the fixed holder, the standard solution for use with one spindle, a rotating holder for CBN and diamond wheels and a dressing bell for small diameters up to 30 mm are available.

The dressing options of the VOUMARD 30 cover all kinds of applications

The VOUMARD 30 is equipped with a Fanuc 0i control system with the latest Kellenberger BLUE Solution software generation, which is now standard on all Voumard and Kellenberger sanding machines. The VOUMARD 30 can be equipped with automation. The special feature: the automation is integrated into the machine casing.

The Hardinge Super Precision T51 lathe with grinding unit will also be on display at the Kellenberger stand (Grinding Hub Hall 8/B60).