The Wilhelm Bahmüller Maschinenbau Präzisionswerkzeuge GmbH, based in Plüderhausen, Germany, demonstrates excellence across several areas: as a renowned manufacturer of fully automated precision grinding machines for large-scale production and fully automated production lines for the corrugated board industry, as well as in the production of precision and clamping tools. These tools are finished on a KELLENBERGER universal grinding machine.

The Company Wilhelm Bahmüller Maschinenbau Präzisionswerkzeuge GmbH has always focused on innovation and the highest quality in its more than 70 years of company history, during which it has developed from its foundation as a mechanical workshop into an internationally active company with around 380 employees and locations on several continents. The strategic and technological pursuit of improvement and further development in all areas of the company is one reason for its continued success.

Hans Binder, Head of Precision Tools Division and in this position responsible for the production of high-precision tools and clamping devices, likewise values strategic partnerships to drive technological innovations. The Precision Tools Division currently has thirty highly qualified employees, and the number is rising. The division generates a good portion of the company’s annual sales with the development and production of tool clamping technology, such as hollow shank tapers, polygon shank tapers, special plate and cassette seat tools, vibration-damped tool holders and alignment adapters, as well as machining process solutions. Nearly 20,000 tools and clamping devices leave the factory every year. Noteworthy here is the fact that Bahmüller Präzisionswerkzeuge is supplier for almost all well-known tool manufacturers. It is not uncommon for these technological partnerships to result in innovative products.

With its team of specialists, Binder also serves the growing market for high-performance special tools from quantity 1, and covers a broad spectrum in this area. Among other things, it was for this reason that only recently the company invested in state-of-the-art grinding technology. The conditions for the procurement were clear: the length of the parts to be ground required the machine to have a center width of 1,600 mm. Furthermore, it should allow the machining of workpieces with a weight of up to 40 kg. Two manufacturers – both based in Switzerland – met the technical and economic parameters in equal measure. Hans Binder explains: “When buying machines, we always pay a lot of attention to quality. We only have high-precision machines in our production, many of them from leading German manufacturers. If several suppliers are on a par in terms of precision, other factors such as flexibility and reliability, commitment to promises, short delivery times and, of course, a good service, can make the difference. For us, Kellenberger is not only a machine supplier, but also a good consultant for manufacturing processes. The most important thing is that we know we are in good hands, whether it’s thanks to the excellent advice or the very good service that comes directly from St. Gallen. Of course, we inquired with other Kellenberger customers in advance. After all, we know each other in the industry. The assessments were consistently excellent.”

Erich Ziegler, Projektleiter Kellenberger und Hans Binder, Leiter Geschäftsbereich Präzisionswerkzeuge bei Bahmüller haben die KELLENBERGER 1000 exakt auf den Bedarf abgestimmt

Country Manager Erich Ziegler is responsible for the German market at Kellenberger. Almost two years ago he teamed up with Hans Binder in configuring the new KELLENBERGER 1000 universal cylindrical grinding machine to best suit the machining tasks: “The KELLENBERGER 1000 is our technically most sophisticated machine solution. It stands for the highest machining and surface quality. According to Mr. Binder’s specifications, the machine was to cover the widest possible range of workpieces and include the processes of internal polygon grinding, internal cylindrical grinding, external cylindrical grinding, external polygon grinding, jig grinding and flute grinding. Due to the length of the workpieces, a center width 1,600 mm and a center height 250 mm were chosen. The machine has two external grinding spindles and one internal grinding spindle, all of which are equipped with direct drive for best results in jig grinding.”

The KELLENBERGER 1000 universal cylindrical grinding machine features hydrostatic guideways in all main axes for maximum form accuracy in grinding tasks with interpolating axes. They ensure very good damping, high rigidity and a constant heat balance, and thus higher process and operational reliability. High positioning speeds and accuracies are guaranteed by direct drives on the rotary axes.

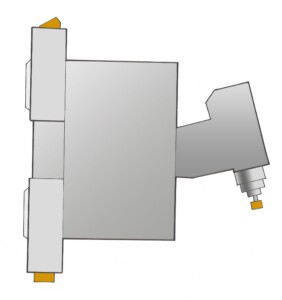

Außenschleifbearbeitung an einer Sonderaufnahme, bei der eine große Spitzenhöhe erforderlich ist.

The solid machine table with the reinforced machine bed brings high static and dynamic rigidity and stability – decisive factors for high precision and high productivity. Due to this stability, parts with a weight of up to 300 kg can be machined on the KELLENBERGER 1000. Power-optimized drives move the longitudinal and cross slides at speeds of up to 20 m/min., with axis resolutions of ten nanometers.

The hydrostatic B axis is equipped with a direct drive. The turret grinding head thus swivels about three times faster than without direct drive and positions with an accuracy of less than one angular second. Particularly when machining requires the swiveling-in of a variety of grinding wheels, non-productive times are thus reduced and, as a consequence, productivity is increased. More than 30 grinding head variants with external and internal grinding spindles allow a wide range of machining options and the perfect application-specific configuration at any time. The large working area enables uniquely optimal grinding wheel positioning. Center heights of 200 to 300 mm and center widths of 1,000 / 1,600 mm are available.

The KELLENBERGER 1000 is equipped with the latest Heidenhain GRINDplus640. In addition to the Heidenhain user interface with operator-guided ISO programming and selective help screens, a Kellenberger user interface with graphical programming and collision monitoring was installed. The control enables higher machining speeds with even greater accuracy. Axis controls in the nano range are the basis for high-precision profiling and path fidelity in contour grinding. The KEL-Remote diagnostics tool with integrated IT security is included as standard with the KELLENBERGER 1000. It ensures higher security when connecting to the customer’s network via VPN tunnel or mobile radio.

Hans Binder is very satisfied with the performance of the machine: “Our requirements regarding accuracy are high. The accuracies that are required and also achieved on the ground mounts are: concentricity for internal and external grinding < 2 µm, axial and cumulative runout < 2 µm, taper-jacket form < 2 µm, diameter tolerances < 2 µm, flatness < 2 µm, squareness < 2 µm. Surface finish Ra < 0.4 µm. Not only does the machine meet our specifications to the best, we have also discovered new applications. Quite possibly, the next machine purchase will again be a KELLENBERGER 1000.”