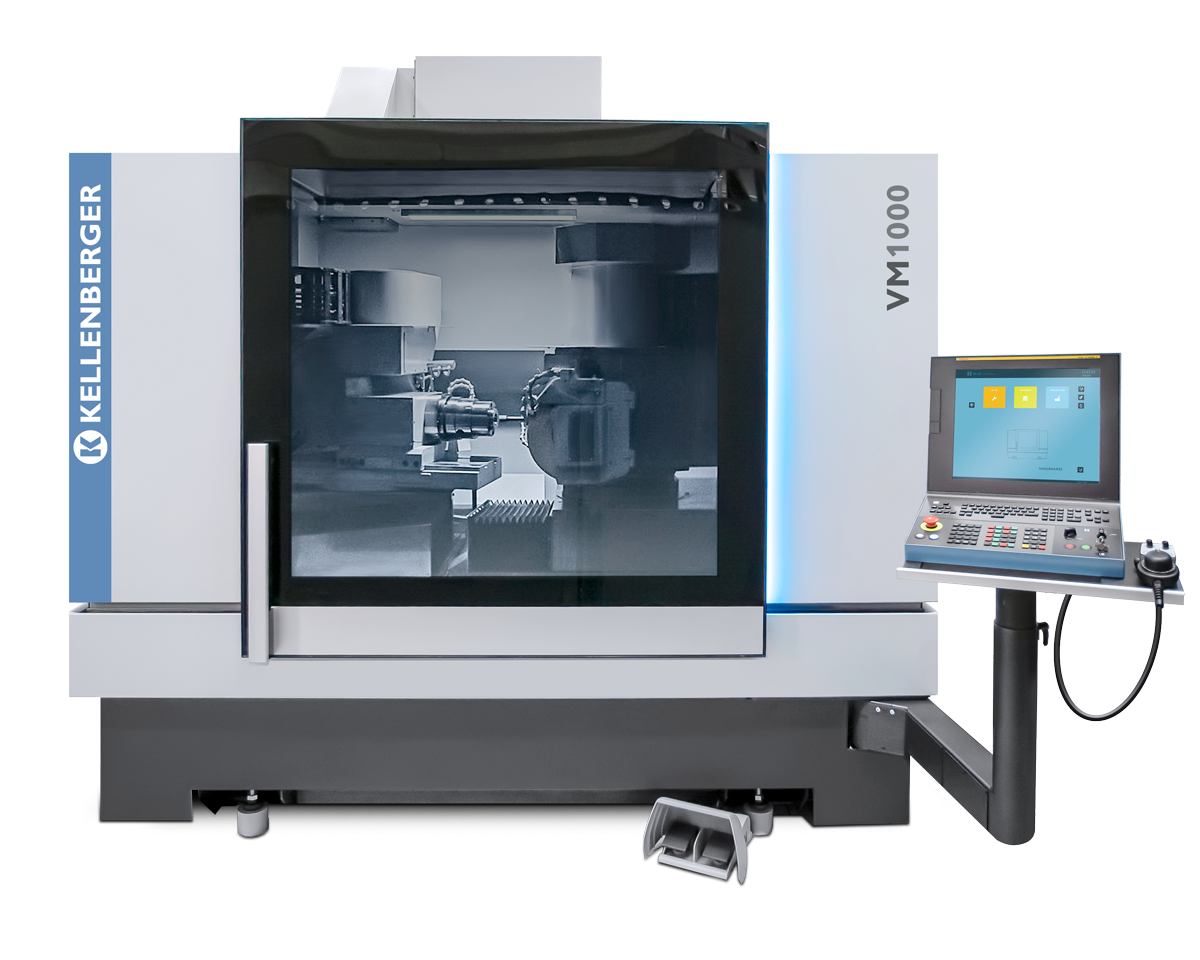

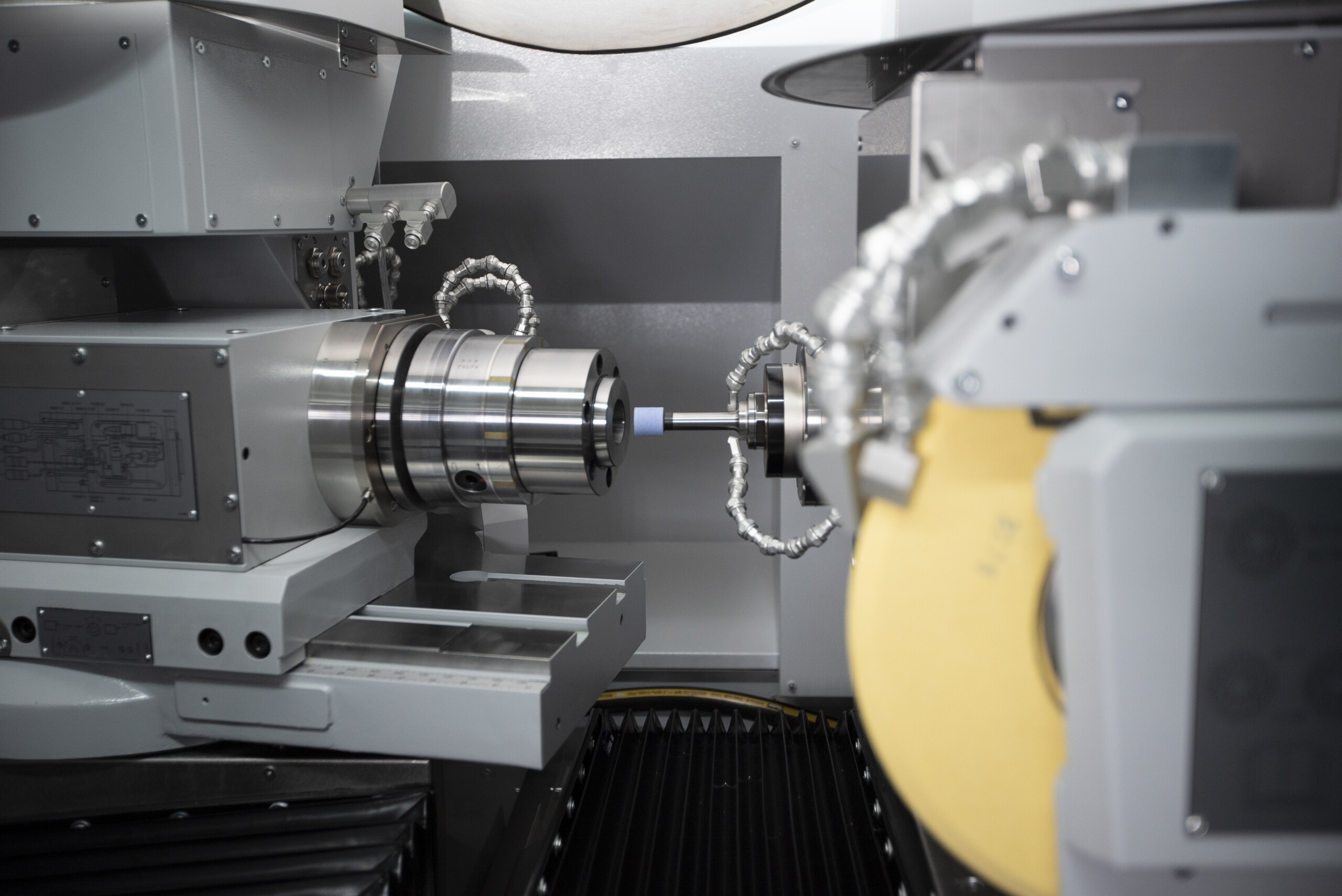

The KELLENBERGER VM1000 is optimized for flexible, universal internal cylindrical grinding of complex workpieces. High-precision chucks, steady rests and fixtures for shoe grinding allow almost any workpiece shape to be machined and several internal and external grinding operations to be carried out in a single clamping operation. The workpieces range from the smallest individual parts for injection systems in car engines, ball bearing rings and gears to hydraulic components and complex components in machine tool construction, such as spindles.

The kinematically flexible machine design of the KELLENBERGER VM1000 has two linear axes and two rotary axes. The hydrostatic linear axes with newly developed HYDROLIN® guides are backlash-free for positioning accuracies in the nanometer range. The high-precision hydrostatic B-axes also perform all necessary movements of the dressing and measuring devices. This flexibility makes a large number of machining variants possible and shortens set-up times. The spindle turret on the B1 axis is equipped with a uniquely compact grinding spindle head with a flexible internal grinding spindle arrangement for a maximum of four grinding spindles.

Operator guidance is via an intuitive 19″ touchscreen interface of the latest FANUC 31i-B CNC control system. The innovative BLUE Solution software enables even inexperienced operators to program quickly and intuitively.