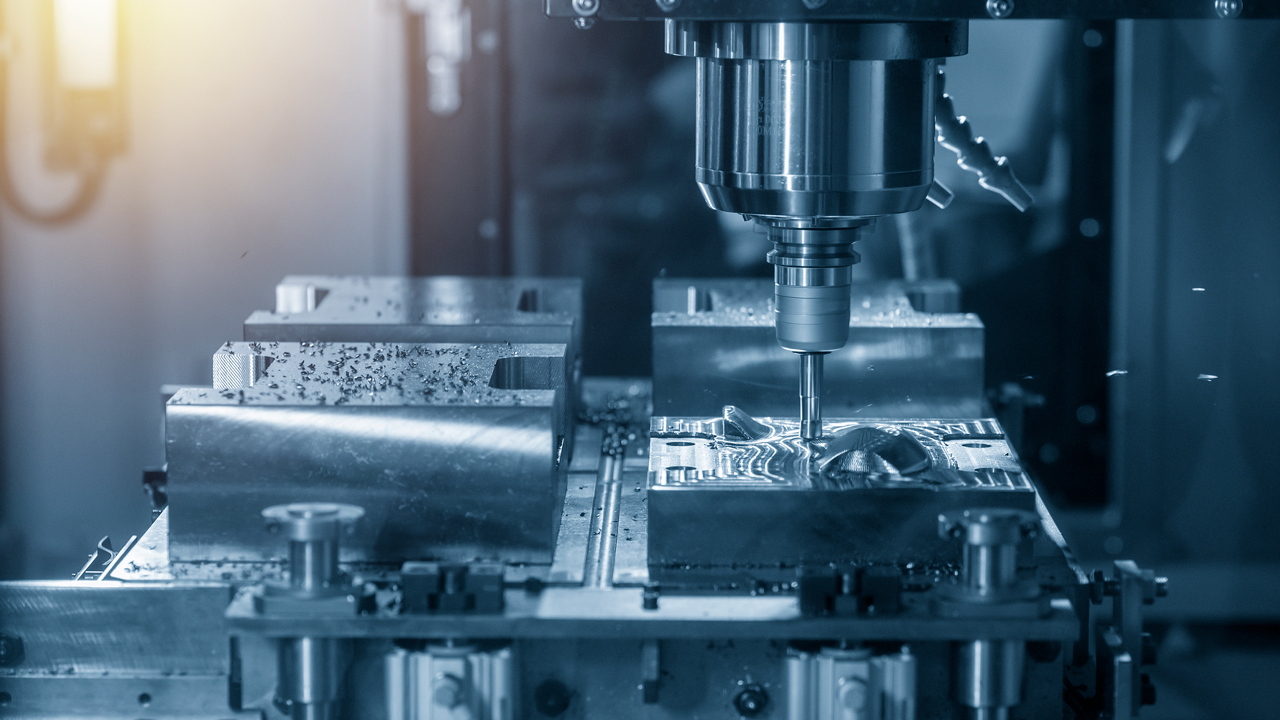

The Kellenberger machine range offers a wide variety of outstanding solutions for grinding, turning, and milling for all industries where maximum precision and flexibility are required. Our series range from universal grinding machines for complex machining tasks to specialized applications. This means we can offer the right solutions for even the most demanding industrial sectors.

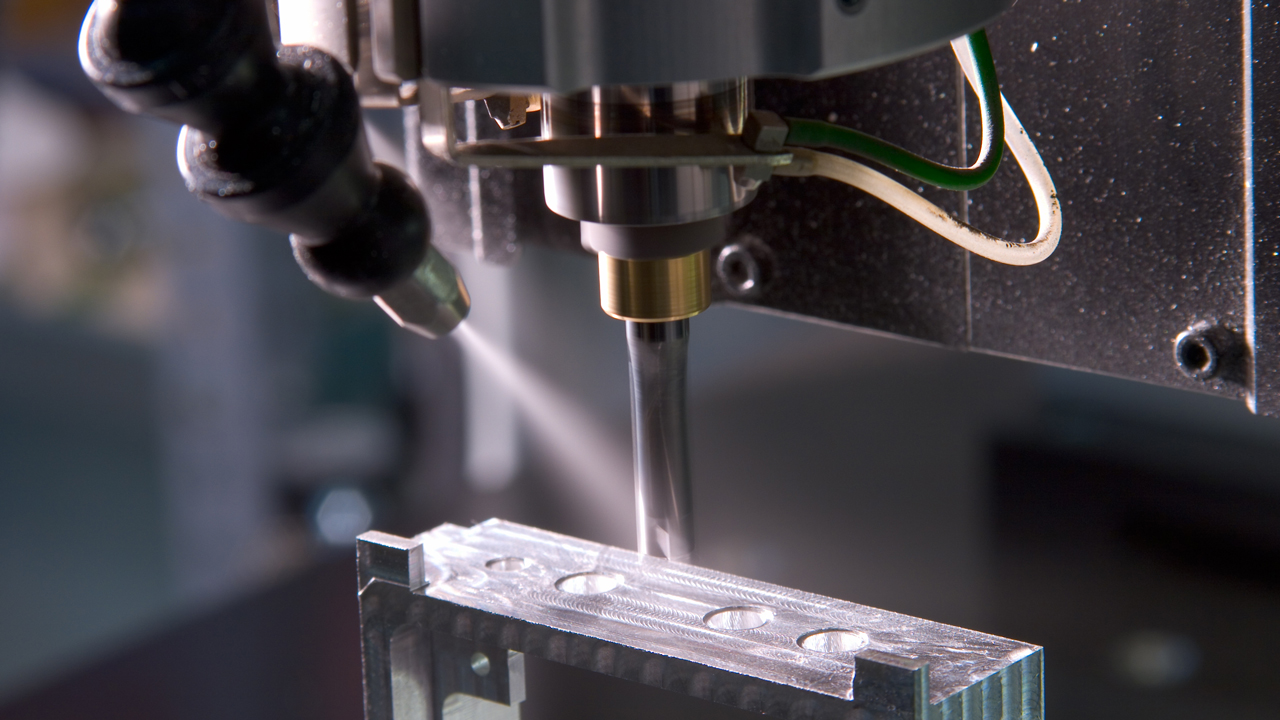

Thanks to their robust, torsion-resistant modules and their consistent design for thermal stability, the KELLENBERGER H2000 and KELLENBERGER H4000 coordinate grinding machines meet all requirements when it comes to maximum precision. The machines in the H series were designed for combined jig grinding and hard milling on a single machine and are used for the most demanding machining tasks, such as in punching tool and mold making, but also for high-precision parts in optical devices or for special precision components. In other words, wherever holes, contours, and shapes with the highest surface quality and tolerances in the low µm range are required.