The name HAUSER has stood for precision engineering in coordinate grinding for more than 110 years. Founded in 1898 by Swiss engineer Henri Hauser, the HAUSER brand remains synonymous with the accuracy and quality standards that are indispensable across various industries.

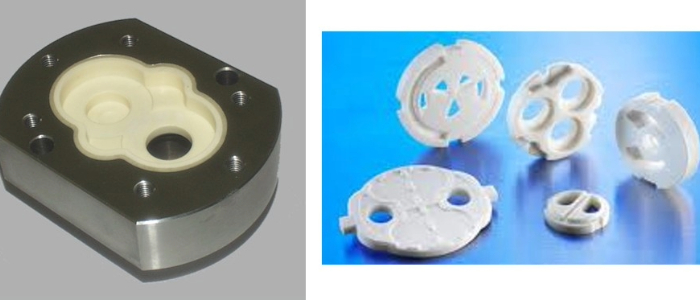

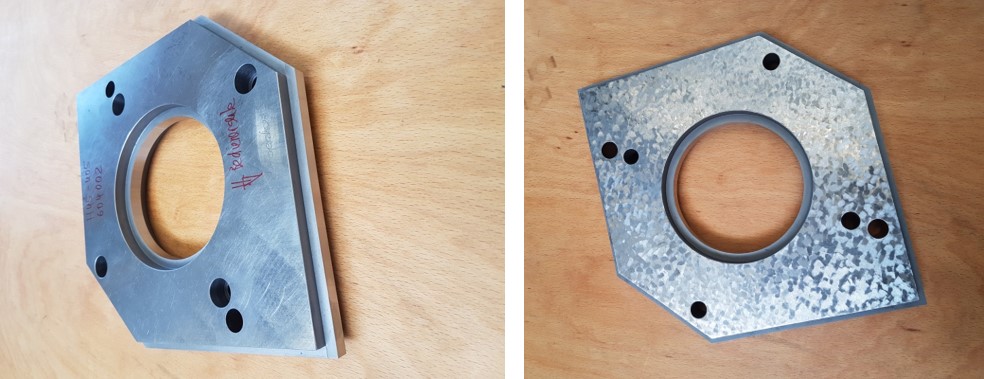

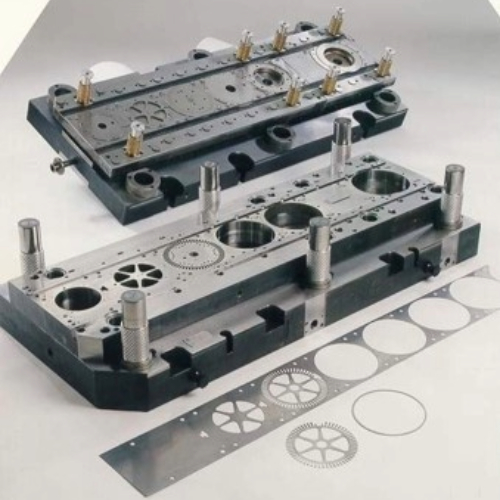

Coordinate grinding machines are primarily used for the most demanding machining tasks in die and mold making, as well as for highly precise components in optical devices or specialized fine mechanical applications. They are essential wherever bores and shapes with the highest surface quality and tolerances in the low µm range are required. Coordinate grinding ensures extremely precise form and positional tolerances.

Additionally, the powerful WHITE Solution software is available on HAUSER coordinate grinding machines. This innovative software optimizes the grinding process, increases efficiency, and enables maximum precision in machining—perfectly tailored to the demands of the most challenging applications.

As part of the Kellenberger Technology Group, the HAUSER brand benefits from the group’s innovative strength, which also extends to the KELLENBERGER, VOUMARD, TSCHUDIN, USACH, and SUPER PRECISION brands. This ensures continuous technological advancements that drive each brand forward in its core area and secure its market leadership.

HAUSER machines are part of the Kellenberger portfolio and can be identified by an ‘H‘ in the model designation, such as KELLENBERGER H2000 or KELLENBERGER H4000.