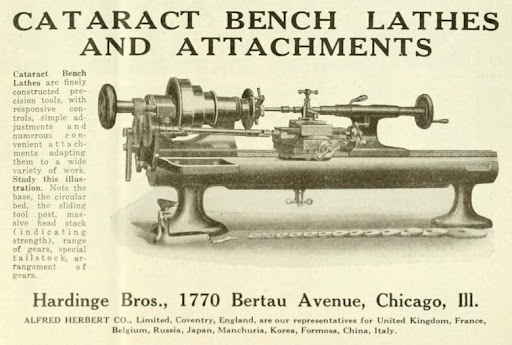

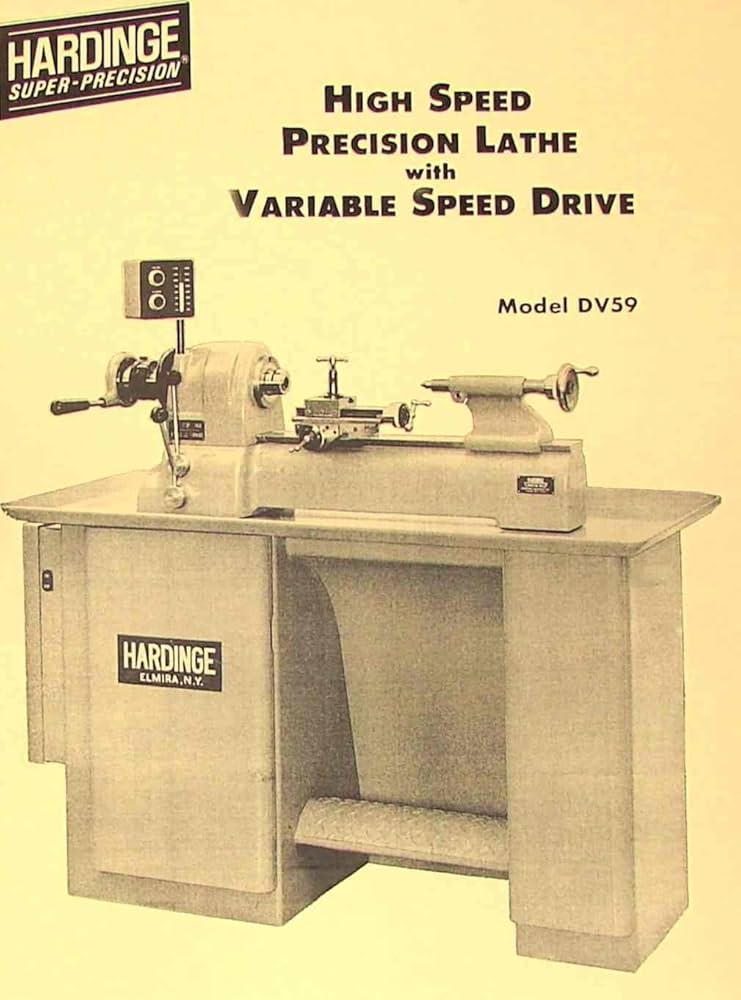

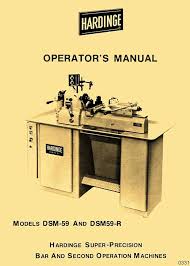

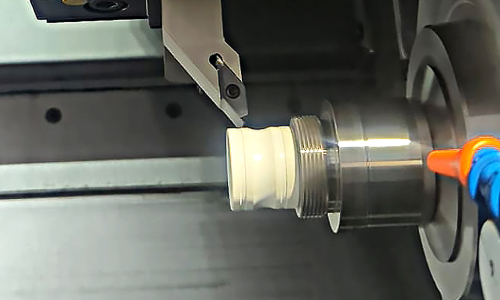

Hard turning or grinding—this debate has been ongoing for years. Each of these technologies has its advantages and can fully leverage them in the right machine concept. Originally developed by the American machine builder Hardinge, the high-precision turning machines of the SUPER PRECISION series are bringing hard turning to the forefront. Due to their rigidity and stability, they are ideally suited for hard/high-precision turning as well as for combined hard turning and grinding operations, allowing for the production of complex workpieces in a single setup.

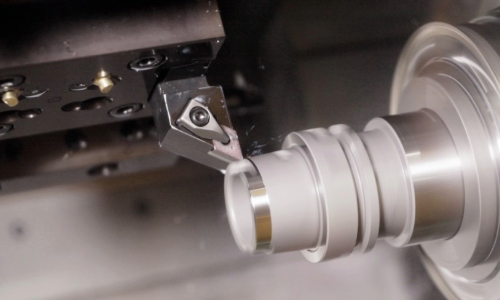

The high surface accuracy achieved in high-precision hard turning on SUPER PRECISION machines allows for complete workpiece processing. This eliminates the need for a grinding process and, consequently, the need to reposition the workpiece on a grinding machine. The result is a reduction in processing times and increased process reliability.

A 45° solid cast iron machine bed, filled with polymer concrete, provides exceptional vibration damping—a crucial prerequisite for accuracies in the micrometer range. Centrally positioned, oversized ball screws and compact, multi-row linear guides ensure that the forces generated during hard and high-precision turning are absorbed effectively.

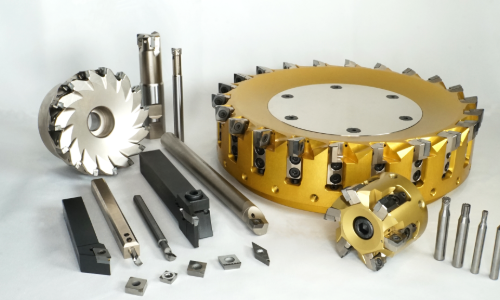

Thanks to numerous options, such as tool and workpiece measurement, grinding attachments, workpiece catchers, bar feeders, and automation systems, each machine can be perfectly adapted to specific machining requirements.

The SUPER PRECISION SP-SERIES is equipped with the powerful MGi (Manual Guide i) software. This intuitive software solution enables the quick and efficient creation of machining programs directly from drawings—regardless of the operator’s experience level. Features such as interactive menus for live-tool machining, 3D simulations of the workpiece and blank, and graphical representations of tools and machining paths optimize the programming process. Additionally, MGi simplifies program adaptation and optimization through functions like copy, paste, and cut, making it easier to refine machining sequences. With these capabilities, MGi software significantly enhances both the efficiency and precision of SUPER PRECISION machines.

Today, the SUPER PRECISION brand is part of the portfolio of the Kellenberger Group and benefits from the innovative strength that also extends to the brands KELLENBERGER, VOUMARD, HAUSER, TSCHUDIN, and USACH. This ensures continuous technological development, strengthening each of these brands in their core competencies and maintaining their market leadership in their respective fields.

SUPER PRECISION machines are part of the Kellenberger portfolio and can be identified by a ‘SP‘ in the model designation, such as KELLENBERGER SP65, KELLENBERGER SP51 or KELLENBERGER SP42.