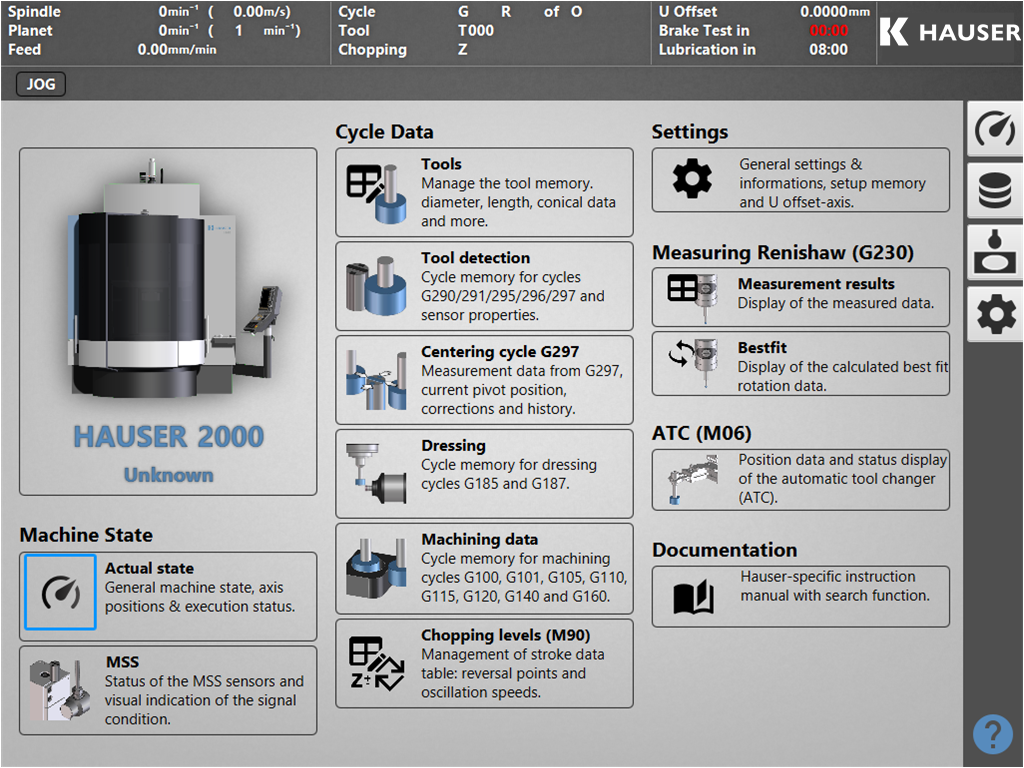

With the WHITE Solution, Kellenberger offers an innovative and user-friendly interface designed specifically for coordinate grinding on the Hauser 2000 series. The software operates with the latest CNC technology, the powerful FANUC 30i-B, ensuring ease of use and maximum process reliability.

Focus on precision and efficiency:

The WHITE Solution has been developed to optimally support the highly precise production of workpieces. It provides operators with all necessary inputs and information in a clear and structured manner, enabling each step to be executed safely and efficiently.

Your benefits at a glance:

- Simple & clear: All relevant inputs and information are well-structured and easily accessible.

- Optimal workpiece alignment: The Bestfit method ensures optimal positioning of the workpiece and minimizes setup time.

- Safe test runs: The Dry-Run feature allows processes to be tested without risk before actual machining begins.

- Intuitive operation: Touch functionality and pictographic representations make the software easy to understand, even for less experienced operators.

- Temperature monitoring: The software displays real-time temperatures of machine components and fluids to ensure consistent quality.

- Flexible machining: The WHITE Solution allows operators to adjust machining data and directly influence the process—without needing to edit ISO codes.

This user-centric operating philosophy supports operators in developing the ideal machining process, while advanced technology ensures the highest precision and reliability.