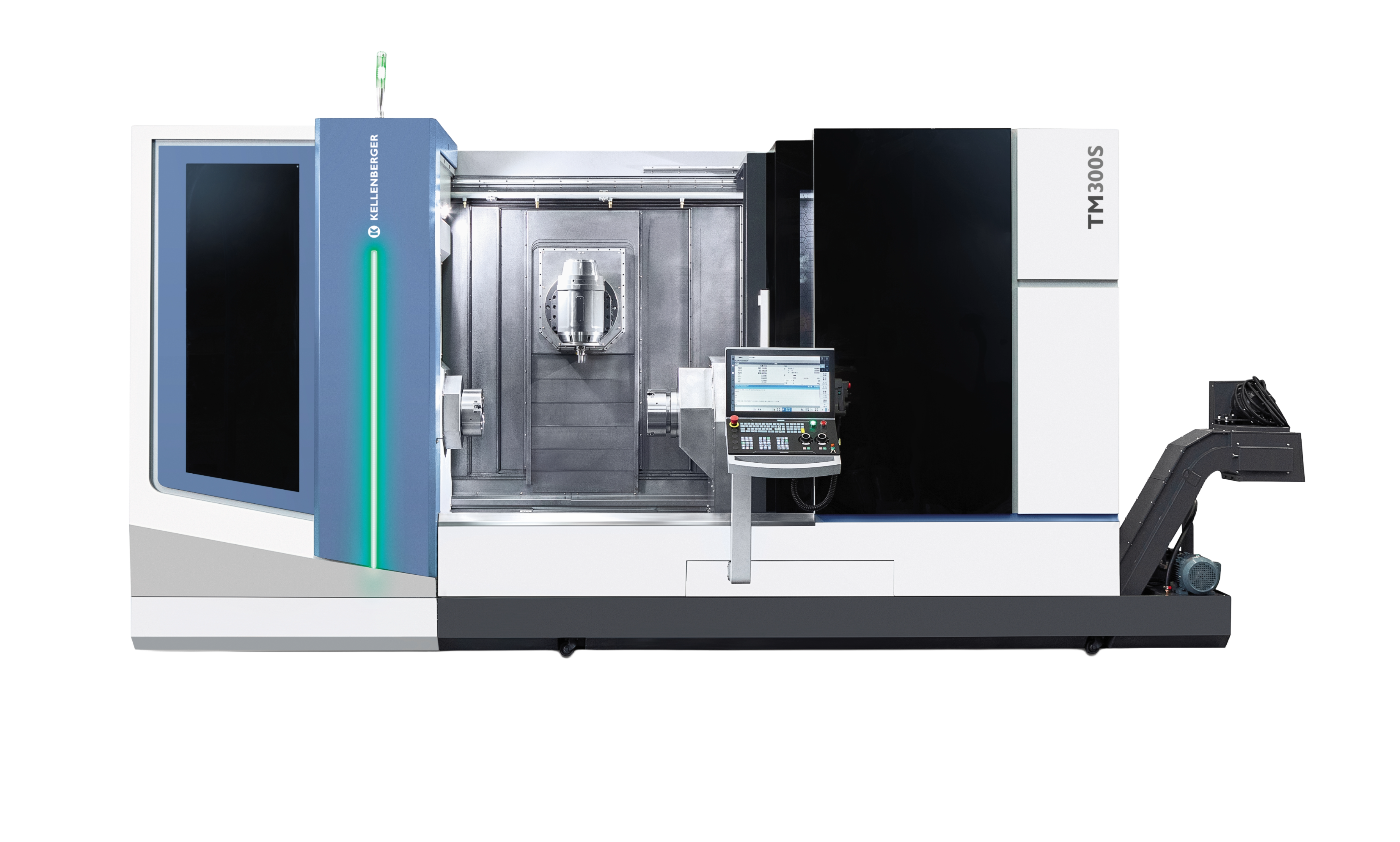

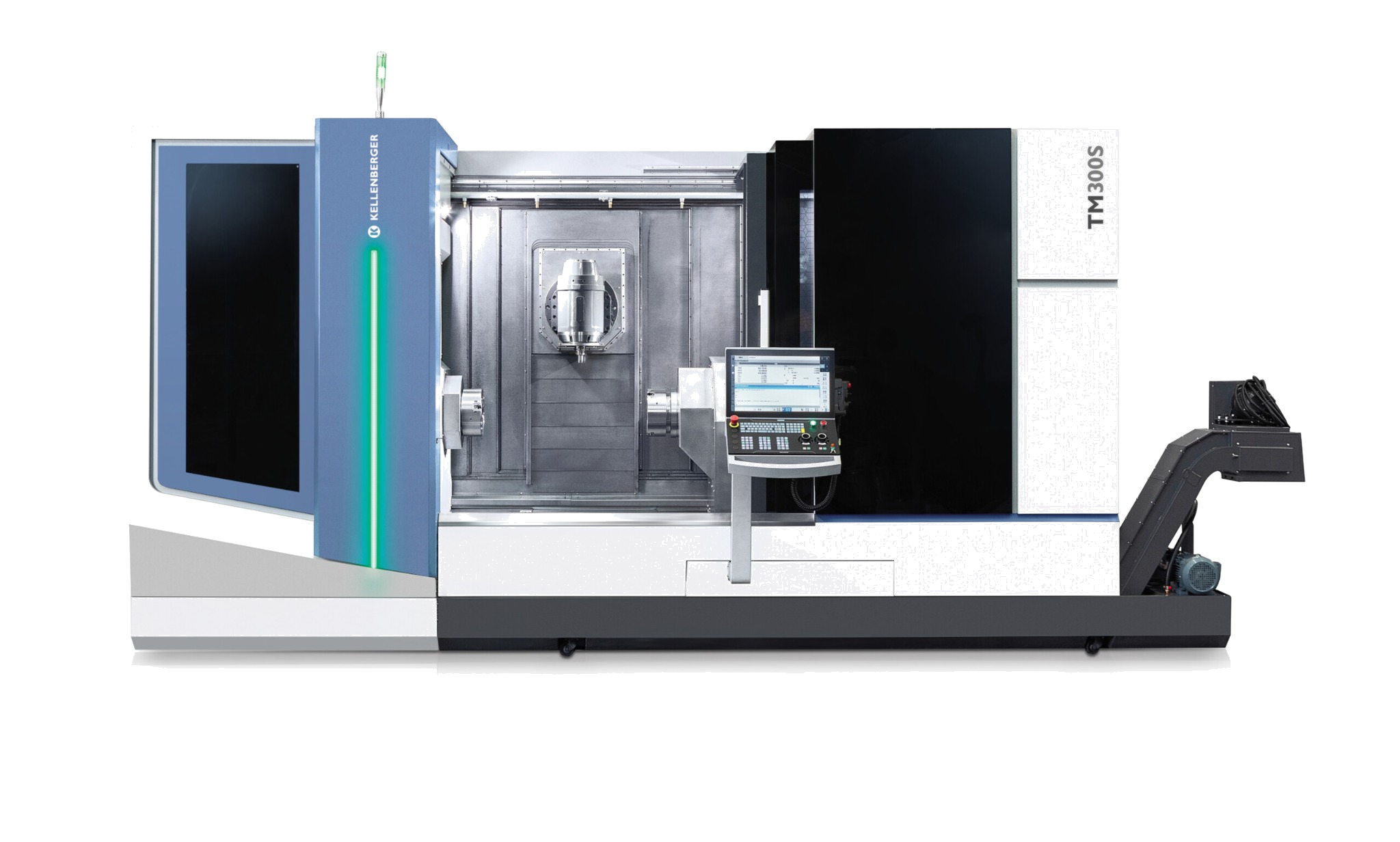

The KELLENBERGER TM300 is a state-of-the-art 5-axis turning-milling center with full closed-loop control. It combines powerful milling and turning capabilities in a single machine, making it ideal for applications in precision engineering, aerospace, medical technology, and general mechanical manufacturing.

KELLENBERGER TM300

Dauer 1:36

FEATURES AND OPTIONS

Key Highlights

- 5-axis simultaneous machining / 6-sided machining in a single set-up

- Orthogonal Y-axis with 300 mm travel for extended machining range

- B-axis with 240° swivel, direct drive for high precision and fast response

- High-torque main spindle (A2-8) with 3,500 rpm and 600 Nm torque

- Milling spindle HSK T63 with 12,000 rpm and 100 Nm torque

- Sub-spindle (TM300S/ST) with 3500 rpm and 477 Nm torque(TM300S)/ 433 Nm torque (TM300ST)

- 40-position tool magazine with automatic tool changer

- Siemens SINUMERIK One with 22″ touchscreen and optional Digital Twin

- Servo tailstock MT5, integrated cooling, air and lubrication systems

Optional Features

- Digital Twin for simulation and optimization of machining processes

- Collision detection, 3D simulation, graphical programming

- Sub-spindle (TM300S/ST) and lower turret (TM300ST) for maximum productivity

TYPICAL APPLICATIONS

- Precision shafts and bushings

- Complex rotationally symmetrical parts

- Medical implants

- Aerospace components with high surface quality requirements