We prioritize durability and longevity in our designs, ensuring that your investment provides value for years to come.

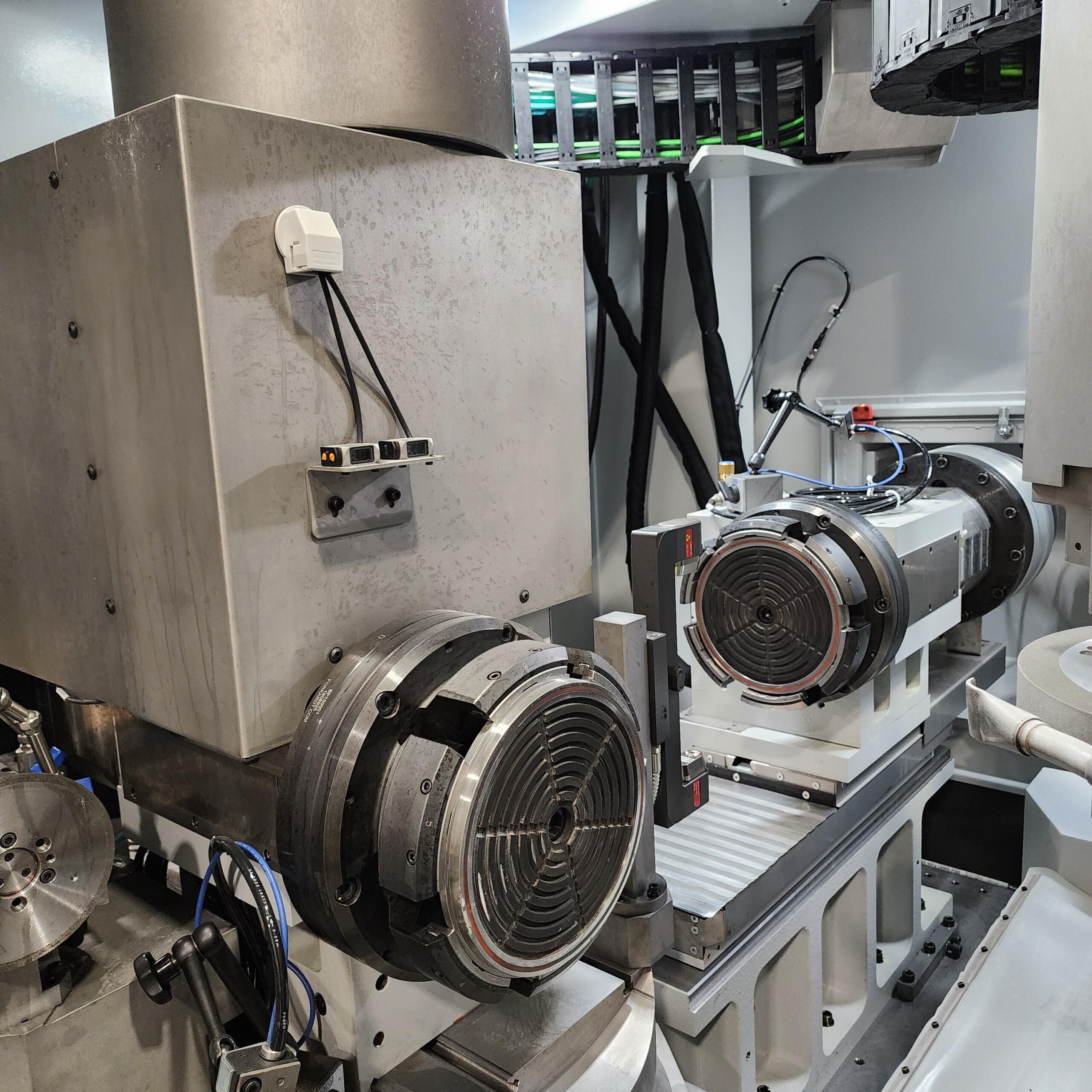

5 axis ID/OD grinder platforms meet the needs of advanced material manufacturers. These Kellenberger machine platforms are ideally suited for high precision grinding applications that require a high level of flexibility. Kellenberger’s ID/OD solutions consolidate functionality, allowing them to extend the typical standard range of grinding machines and provide more complex automated processes in single setups. ID, OD, Bevel, Face, Radius, and Small Feature Grinding processes using roughing and finishing wheels may be combined to achieve higher surface finishes and consistent part quality.