Machine automation has long been a major topic in every production environment, as it allows for entire shifts to be operated without human intervention or enables multi-machine operation during regular shifts. At Kellenberger, we continuously focus on automation solutions for our series KELLENBERGER K100, KELLENBERGER K1000, KELLENBERGER VM30, KELLENBERGER VM1000, KELLENBERGER T1000, and KELLENBERGER H2000. These solutions are optimally tailored to significantly increase flexibility in manufacturing for our customers. We offer both standard automation and customized solutions.

AUTOMATION

OUR SOLUTIONS

SMART AUTOMATION. MAXIMUM EFFICIENCY

BENEFITS OF OUR AUTOMATION SOLUTIONS

- Increased Efficiency: Automation reduces the need for manual intervention, allowing for more consistent and efficient production processes.

- Cost Savings: By reducing labor costs and minimizing errors, automation can lead to significant cost savings over time.

- Enhanced Flexibility: Our automation solutions are designed to be adaptable, allowing for quick changes in production processes to meet varying demands.

- Improved Quality: Automation ensures precision and consistency, leading to higher quality products and reduced waste.

- Safety: Automated systems can handle hazardous tasks, reducing the risk of injury to workers.

OUR APPROACH

- Consultation: We work closely with our customers to understand their specific needs and challenges.

- Customization: We develop tailored automation solutions that fit seamlessly into existing production lines.

- Implementation: Our team of experts ensures smooth installation and integration of automation systems.

- Support: We provide ongoing support and maintenance to ensure optimal performance of our automation solutions.

At Kellenberger, we are committed to helping our customers achieve their production goals through innovative and reliable automation solutions. Contact us today to learn more about how we can help you enhance your manufacturing processes.

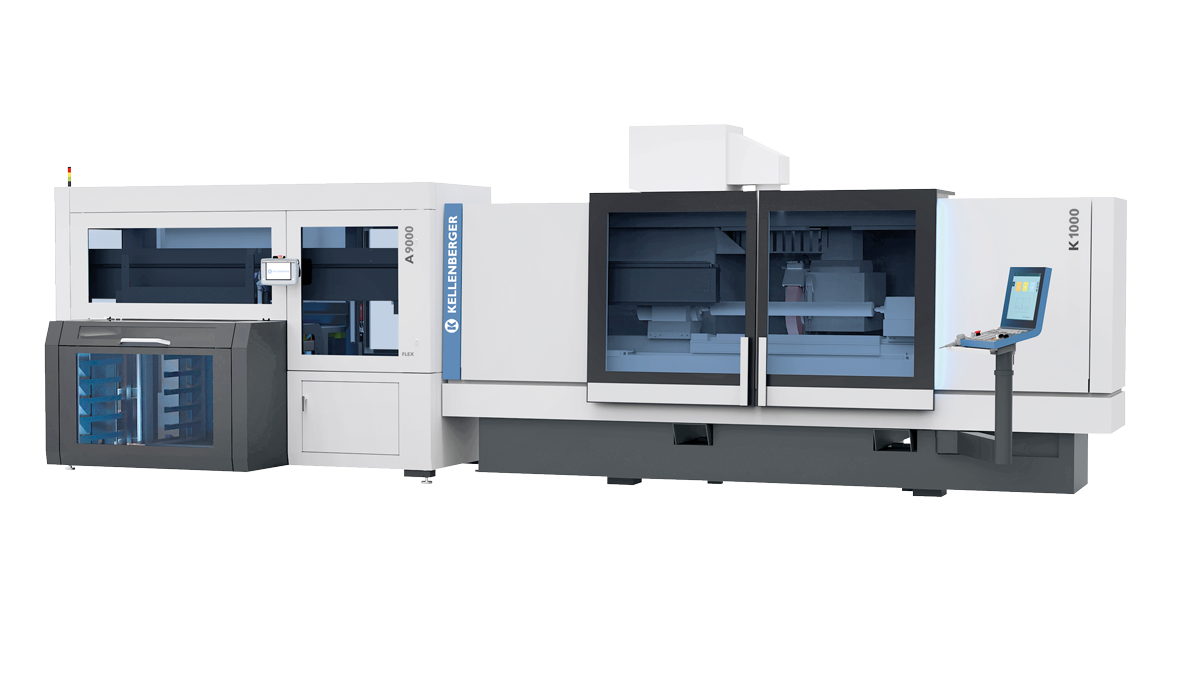

KELLENBERGER A9000 FLEX

The Ultimate Automation Solution for Precision Grinding

The KELLENBERGER A9000 FLEX is Kellenberger’s advanced customized pallet automation system, designed for shaft and chuck parts. With its telescopic gantry beam, it ensures seamless operation without interfering in the machine room.

Key Features:

No gantry beam in the machine room – Maximized workspace efficiency

Quick-change gripper heads – Effortless transition between shaft and chuck parts

Autonomy of 9 pallets – Increased productivity and minimal operator intervention

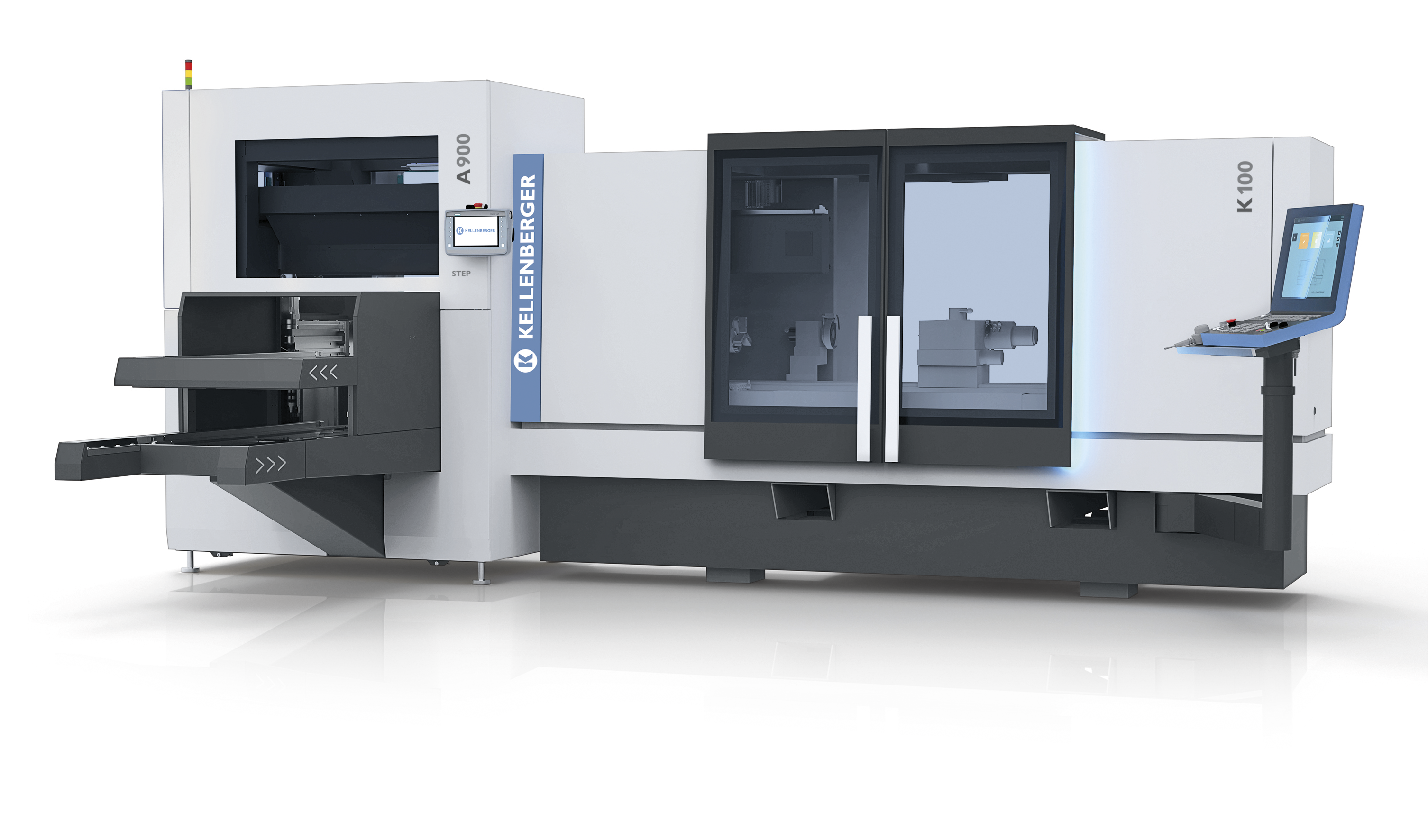

KELLENBERGER A900 STEP

The Universal Automation Solution

The KELLENBERGER A900 STEP is a versatile automation system designed for all Kellenberger machine series. It offers seamless handling of shaft and chuck parts, ensuring maximum flexibility and efficiency in your production.

Key Features:

Compatible with all Kellenberger machine series

Quick-change gripper heads – Easy switch between shaft and chuck parts

Autonomy of 5 pallets – Reliable and efficient operation

Additional options available – Including blow-off and measuring solutions for enhanced precision

KELLENBERGER A90 FLY

The Compact and Cost-Effective Automation Solution

The KELLENBERGER A90 FLY is the ideal universal loader for starting automation. Designed specifically for shaft parts, it offers a small footprint while ensuring high efficiency and reliability.

Key Features:

Designed for shaft parts – Optimized handling and precision

Small footprint – Space-saving design for easy integration

Cost-effective solution – Affordable entry into automation

Autonomy of 2 pallets – Expandable up to 5 pallets for increased flexibility

KELLENBERGER A90 REX

The Efficient and Fast Automation Solution

The KELLENBERGER A90 REX offers a small footprint and a cost-effective solution for automating your production. Designed for fast integration, it ensures quick set-up times and smooth changeovers, making it an ideal choice for manufacturers looking to boost productivity without compromising on efficiency.

Key Features:

Small footprint – Compact design for optimal space utilization

Cost-effective solution – Affordable and efficient automation

Short delivery time – Thanks to standardization for quick deployment

Quick set-up and changeover – Streamlined processes for faster turnaround

Request

I am interested in a machine