Automated processes to combat skill shortage

What should be done when a high order intake leads to production bottlenecks? For gear pump manufacturer Maag, the answer was obvious. When purchasing a KELLENBERGER K1000 cylindrical grinding machine in 2023, the company opted for an automation solution by Kellenberger, which is precisely tailored to the workpiece and workflow, including a pallet changer and robotic arm.

Maag is a leader in the manufacture of all types of gear pumps for the polymer, chemical, petrochemical, pharmaceutical, and food industries and delivers to nearly every country in the world. Since its founding in 1913, the company has secured a top position in the industry through extensive expertise, know-how, and dozens of patents. Each year, more than 2,000 pumps of various sizes leave the plant in Oberglatt near Zurich.

An extremely strong order situation in 2022 created an exceptional challenge for the company in effectively managing the workload. At the time, most of the machines in the production fleet were either over- or under-dimensioned for the wide range of workpiece sizes. This often resulted in long waiting and processing times.

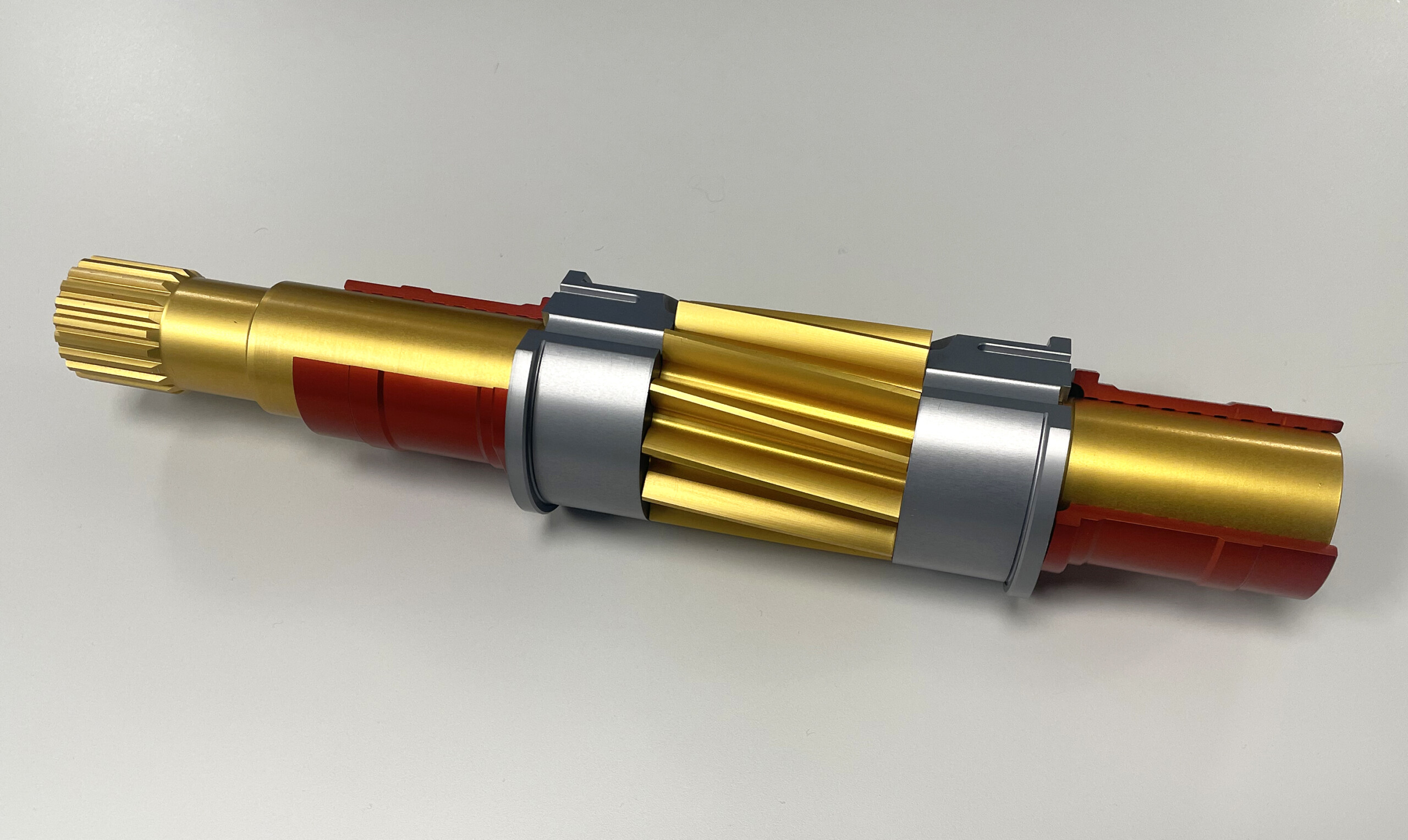

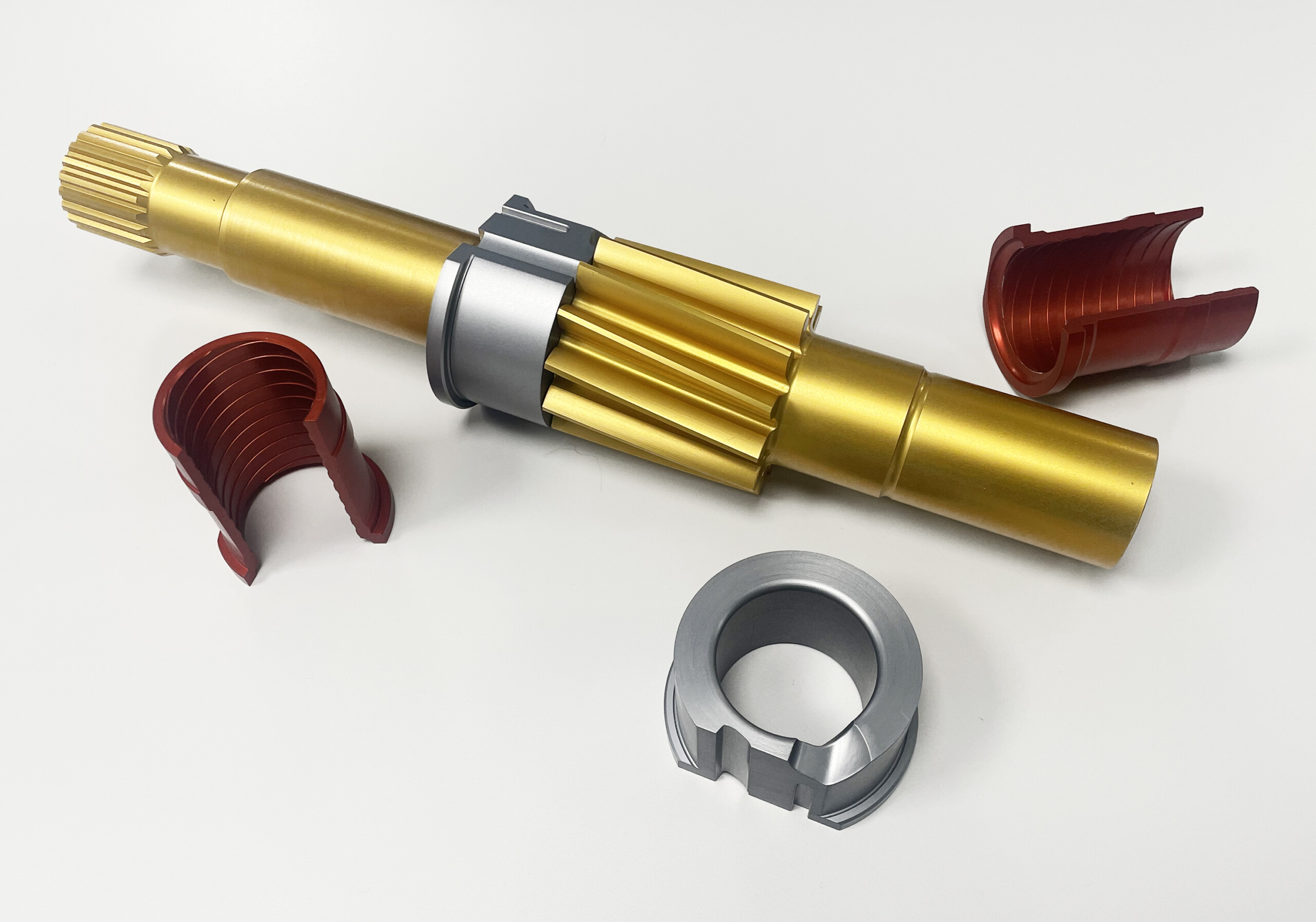

Gear pumps consist of many individual parts that must be manufactured with high precision, to ensure fault-free operation

Thomas Lutz, Head of the Cylindrical Parts Department and with the company for 32 years, recalls: “We were working in three shifts, doing overtime – even on weekends – to meet delivery deadlines, and even outsourced some of the machining.” For Production Manager Kristian Osrecak, who has been with Maag for 25 years, it quickly became clear that the high costs of outsourcing and the administrative effort involved in coordinating schedules with suppliers were not sustainable long-term solutions. The acquisition of a grinding machine that precisely matched the workpieces, combined with a custom-tailored automation system, was intended to put an end to that.

“We were actually quite well equipped in terms of our grinding capabilities,” Osrecak explains. “Here at our Oberglatt plant, we had grinding machines from three well-known manufacturers at the time. And at our Maag Italy competence center in Rozzano, where our industrial pumps are produced, we were already using two Kellenberger machines—one U1000 and one KELLENBERGER K100. Now we had to determine which of these grinding machine manufacturers could offer the right automated solution for our needs. When acquiring new machines, it’s standard for us to request quotes from at least three suppliers. If the specifications are the same, price becomes the deciding factor. However, one of the Swiss machine builders we contacted didn’t submit a quote at all.”

Convincing concept for machine and automation

“The most convincing concept in terms of machine and automation ultimately came from Kellenberger,” says Thomas Lutz. “What also impressed us was the clean and structured execution of the project and the professionalism shown by the Kellenberger representative responsible for us, Daniele Corso.”

The KELLENBERGER K1000 with pallet tower and robot has taken sanding processing at MAAG to a new level. Thomas Lutz and Kristian Osrecak (here with Marco di Maggio, center) are satisfied with the solution.

The automation solution offered – featuring a pallet changer and robot –is one of many options in the Kellenberger portfolio, which is designed to offer a suitable automation solution for every machine and machining requirement. To achieve this, Kellenberger collaborates with the most capable automation specialists in Europe. And if the wide range of standardized solutions should ever fall short, custom solutions are developed.

The automated system holds a total of 12 pallets. Depending on the size of the parts, between 36 and 100 workpieces can be set up

Highest precision easily automated

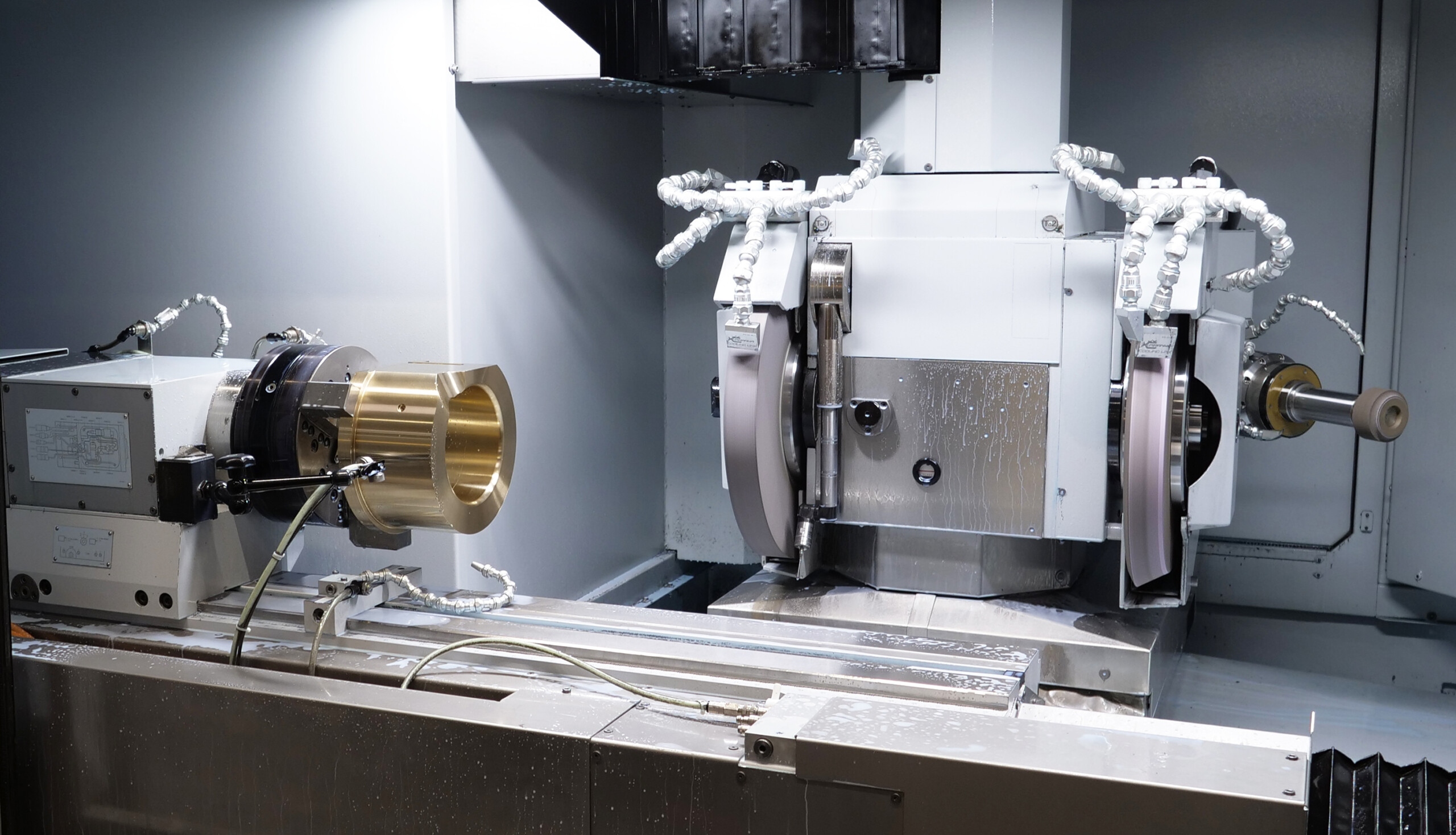

The KELLENBERGER K1000 features hydrostatic guideways on all main axes, ensuring maximum form accuracy for grinding tasks involving interpolating axes. The CNC-controlled B-axis for the grinding head is also hydrostatic, meaning it is free from wear. It is equipped with a direct drive, a water-cooled high-torque motor, and an angular encoder with a resolution of 0.1 arcseconds. This allows the turret grinding head to swivel approximately three times faster and position with an accuracy of less than one arcsecond. Especially in applications requiring the swiveling of different grinding wheels, this significantly reduces idle times and boosts productivity.

The KELLENBERGER K1000 is optionally available with center distances of 1,000/1,600 mm and center heights of 200, 250, or 300 mm. Of the more than 30 different grinding head configurations with external and internal grinding spindles available as standard – covering virtually every machining requirement – Maag selected a configuration with two external grinding spindles and one high-frequency internal grinding spindle with a maximum speed of 42,000 rpm.

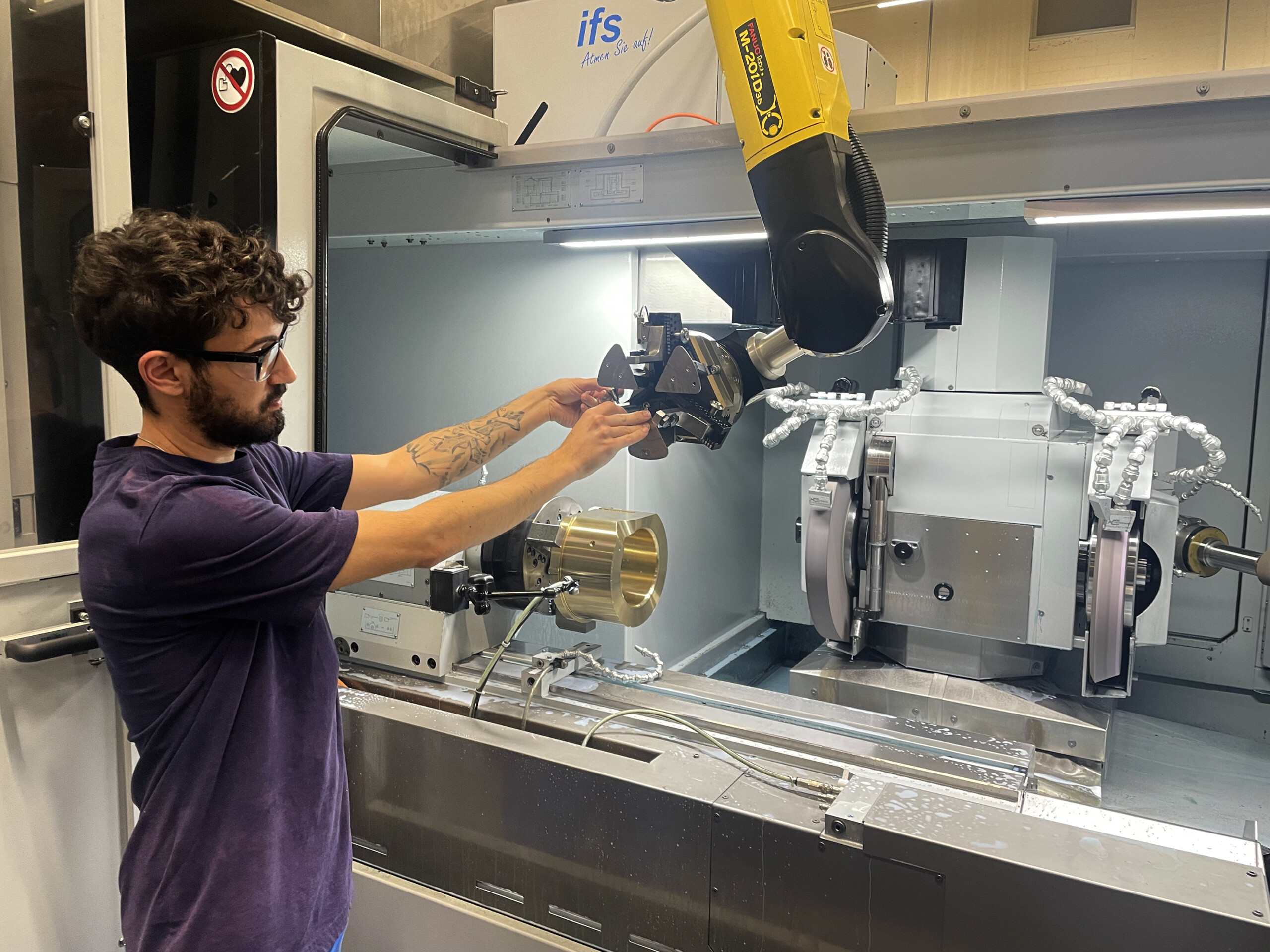

“The machine and automation were tailored to our wishes and specifications,” explains Thomas Lutz. “Our workpieces have specific machining requirements due to the high precision demanded. For example, we needed two measuring probes to monitor the runout of the rear face and the diameters of the bores during machining. Additionally, we required a 3-jaw chuck on the robot to ensure secure clamping of the parts. The many options offered by the KELLENBERGER K1000 leave virtually nothing to be desired.”

The robot has a 3-jaw chuck for the safe transportation of the workpieces. The processing time for this aluminum bronze workpiece is between 45 minutes and one and a half hours.

Quick and easy programming with the control software BLUE Solution

Like all Kellenberger machines, the KELLENBERGER K1000 is equipped with the innovative BLUE Solution control software specially developed by Kellenberger for sanding, which is easy and logical to use for all operators – even inexperienced ones. The operating elements are clearly arranged on the touchscreen and can be quickly identified and selected. The user receives maximum support when entering data. A plausibility monitor indicates incorrect entries, allowing the operator to make adjustments.

The clearly structured interface, divided into the three main areas –Setup, Programming, and Production –and the three secondary areas – Diagnostics, Settings, and Functions –makes setting up the machine for a new production process easier than ever. The BLUE Solution software includes modules for non-circular and thread grinding, as well as a regrinding cycle. For more complex grinding tasks like thread grinding, the BlackCam version is used.

Quick and easy programming with the control software BLUE Solution

Like all Kellenberger machines, the KELLENBERGER K1000 is equipped with the innovative BLUE Solution control software specially developed by Kellenberger for sanding, which is easy and logical to use for all operators – even inexperienced ones. The operating elements are clearly arranged on the touchscreen and can be quickly identified and selected. The user receives maximum support when entering data. A plausibility monitor indicates incorrect entries, allowing the operator to make adjustments.

The clearly structured interface, divided into the three main areas –Setup, Programming, and Production –and the three secondary areas – Diagnostics, Settings, and Functions –makes setting up the machine for a new production process easier than ever. The BLUE Solution software includes modules for non-circular and thread grinding, as well as a regrinding cycle. For more complex grinding tasks like thread grinding, the BlackCam version is used.

Machine operator Marco di Maggio now has full command of the BLUE Solution software.

At Maag, they initially worked extensively with the BLACK CAM software. “Programming with the BLUE Solution turned out to be more challenging than we had expected and took time,” says Kristian Osrecak. “Combining the machine with automation was quite a complex affair, and it took us a good while to get all the fine details sorted out.” “We had to enter a lot of data for a wide range of machining steps – starting with radius grooving, through to the complete machining of the front and rear bearing faces, including overall width, collar width, radius, and both outer and inner diameters. And all of that for around 80 to 100 different parts, in batch sizes ranging from 4 to 40. The two measuring devices had to be implemented into the control system as well.”

Thomas Lutz agrees: “Many factors influence the result during machining. With such a complex system, the correct interaction between the machine, automation, grinding media, and clamping devices is crucial. Everything has to work in harmony for us to achieve the high quality required for our parts. During the setup phase, however, we received excellent support from Kellenberger.”

In the meantime, the KELLENBERGER K1000 is running around the clock in three shifts. Two employees take turns operating the machine, and the third shift runs unattended. “As hoped, the automated KELLENBERGER K1000 has drastically increased our productivity! The backlog and the many overtime hours are finally a thing of the past,” Thomas Lutz and Kristian Osrecak agree.

The spindle configuration with two external grinding spindles and one high-frequency internal grinding spindle enables a wide variety of machining operations.