High-Precision Grinding for Clamping Technology “Made in Black Forest”

Sterman Technische Systeme GmbH, a family-owned company based in the Black Forest, has stood for technologically outstanding special solutions in the field of clamping technology for 25 years. Demanding customers appreciate the high quality of the products. This is due in part to the high-precision grinding machines from Kellenberger.

The name Sterman comes up whenever high-quality standard solutions, available on the market in the field of clamping technology, are not sufficient. The “Black Forest inventors,” as they confidently call themselves, take on anychallenge that goes beyond the norm – and do so with a level of precision that is second to none. The company calls this approach “µ-thinking” and justifies the pursuit of perfection by stating that without precise clamping, no accuracy can be achieved on the workpiece, and some processes would not even be possible.

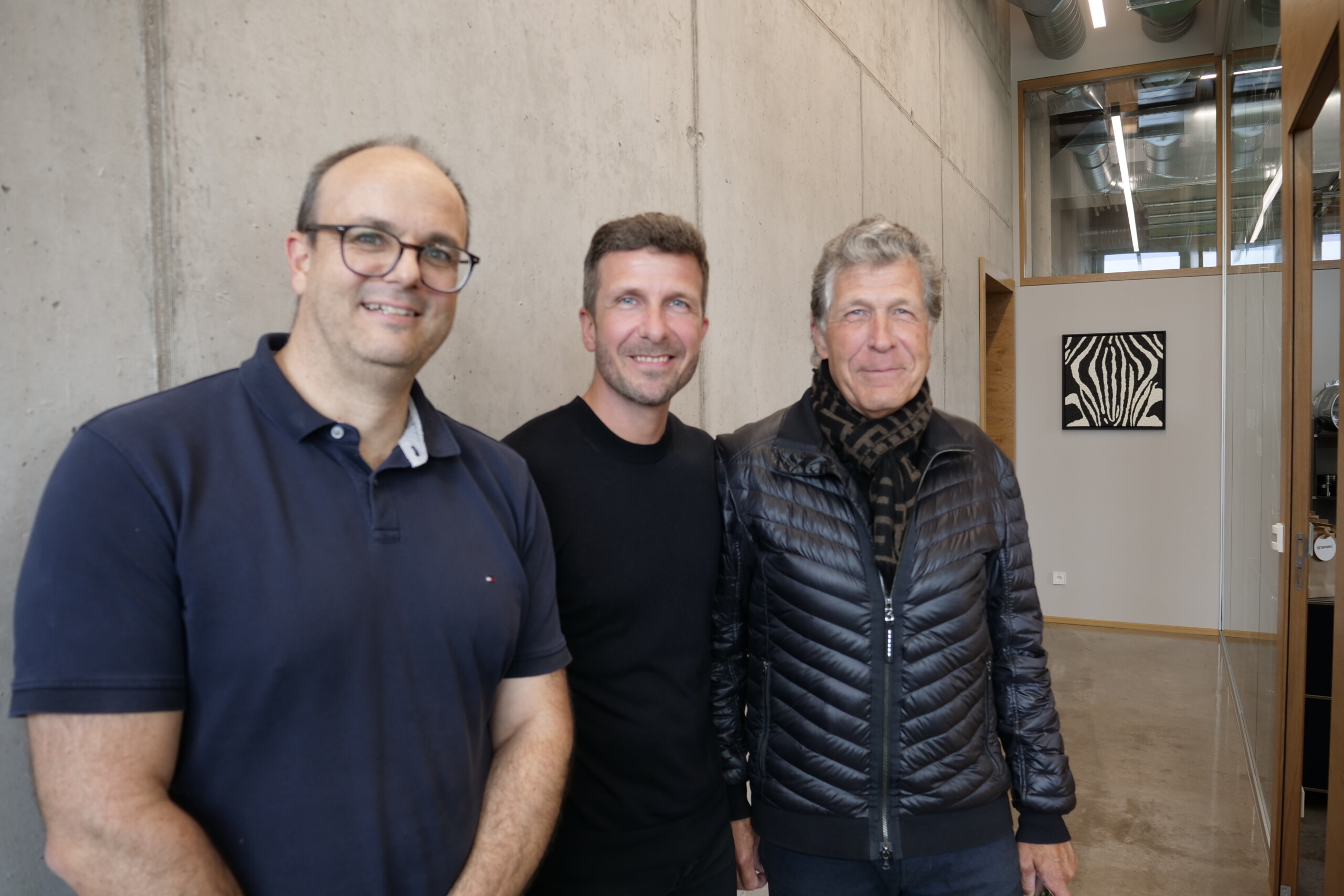

For three generations now, Sterman has drawn on a deep well of experience in all aspects of special clamping technology. Company founder Peter Stermann and his father Vid Stermann managed the special design office of a large, renowned clamping technology manufacturer until 1999, His conviction that combining design and production under one roof would ensure the highest product quality led Peter Stermann to establish his own company in 2000. Johannes Stermann, the third generation, has held a management position in the company since 2012.

Many well-known customers from the automotive sector, aerospace, medical and cleaning technology, metrology and balancing technology, as well as alternative energy, subsequently commissioned the young company — laying the foundation for its ongoing success to this day.

Committed to the µ: Mike Zinapold, Johannes Sterman, and Peter Sterman

The modern company headquarters in St. Georgen-Peterzell currently comprises 3,500 square meters of development and production space. With a team of 60 employees, Sterman today not only works on tailor-made clamping systems and more complex fixtures.

Increasingly, special-purpose machines are also being developed, designed, and built in close collaboration with customers for specific applications. These, too, must meet the highest precision standards – such as a system for Bosch used to manufacture clutch discs for converters in electric motors. Sterman was involved in the development phase of the innovative axial flux motor for Mercedes-Benz. More than 20 patents testify to the company’s innovative strength. A vertical range of manufacture of over 85% to 90% for the clamping systems ensures that its expertise stays in-house.

But what exactly is this “µ-thinking” that Sterman is committed to? Mike Zinapold, mechanical engineer (Dipl.-Ing.) and a part of Sterman since graduating, explains: “By µ-thinking, we mean the consistent ultra-precise alignment of our products and solutions with the individual requirements of our customers. As the smallest mechanical unit, the µ is our benchmark. In intricate manufacturing processes, the right clamping technology simply makes all the difference!”

Special machine construction is also a complex matter. This assembly cell is equipped with 27 NC axes

Three generations of Kellenberger Machines

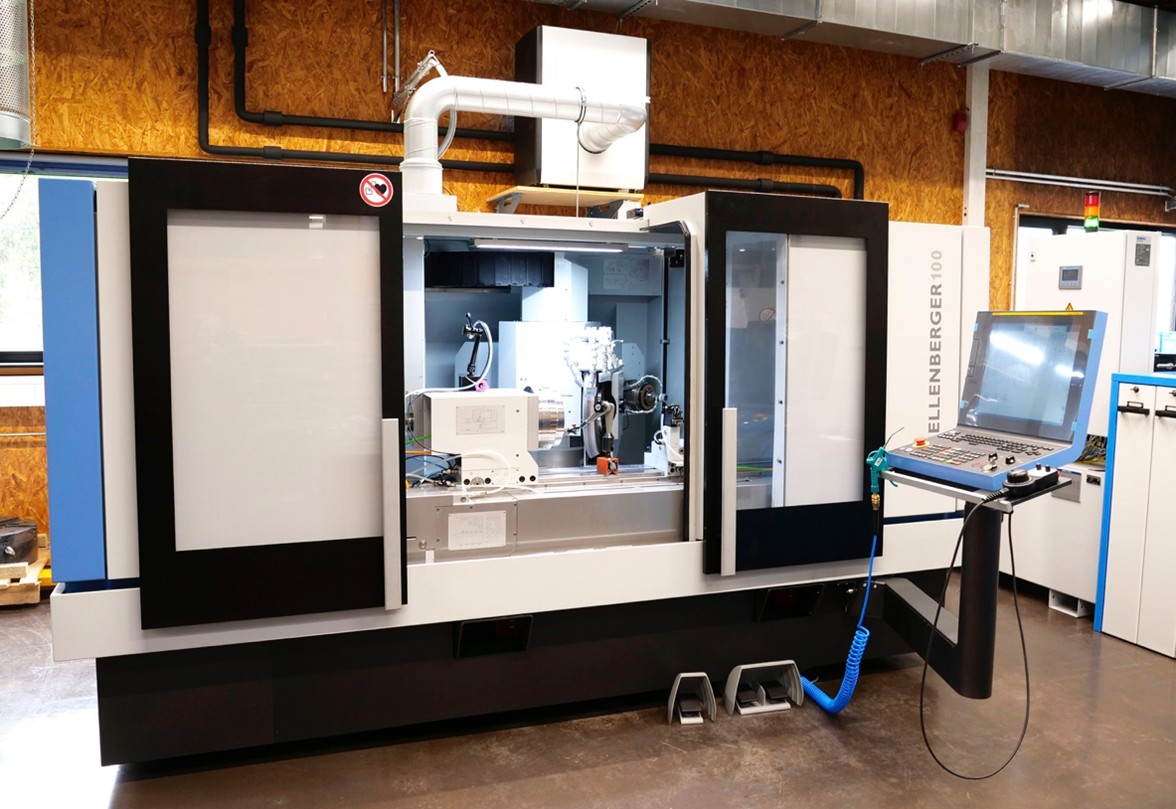

Sterman’s machinery fleet is excellently equipped, featuring 15 machining centers, primarily from German and Swiss manufacturers. In the grinding department, three generations of Kellenberger grinding machines from different series stand side by side. The two latest are the universal cylindrical grinding machines KELLENBERGER K100 and the Voumard 1000 (now listed in the portfolio as KELLENBERGER VM 1000). The latter particularly excels in internal grinding, where it effortlessly delivers top-level precision even with the smallest diameters.

In the future, the K100 is set to replace an older Kellenberger KEL-Varia in production. This machine was the predecessor of today’s Kellenberger premium class K1000. However, the team consciously chose the smaller K100 as a replacement. “The K100 is slightly more compact, which is a real advantage given our space constraints, and in terms of performance, it is ideally suited for our machining tasks,” says Mike Zinapold. “And with the Voumard 1000, we already have one of Kellenberger’s most powerful premium-class machines.”

The KELLENBERGER K100 was developed for the high demands of precision manufacturing of prototypes as well as small and medium series.

The two machines offer a wealth of advanced technology. The K100 offers 10 grinding head variants, providing a wide range of configuration options for various grinding operations. Its powerful grinding wheel drive boosts productivity, while the newly developed Z-axis guide ensures high profile accuracy. The direct-drive C-axis delivers enhanced precision, even in non-circular grinding applications. The K100 is available with center widths of 1,700, 1,000 mm and 600 mm and center heights of 200 and 250 mm.

Two tailstock options are available: a standard version for workpieces up to 100 kg and a reinforced version for up to 150 kg. An optional synchronous tailstock with automatic fine adjustment allows for complete machining of shafts without a driver, enabling full-length processing of a workpiece.

The K100 is equipped with an in-process measuring probe

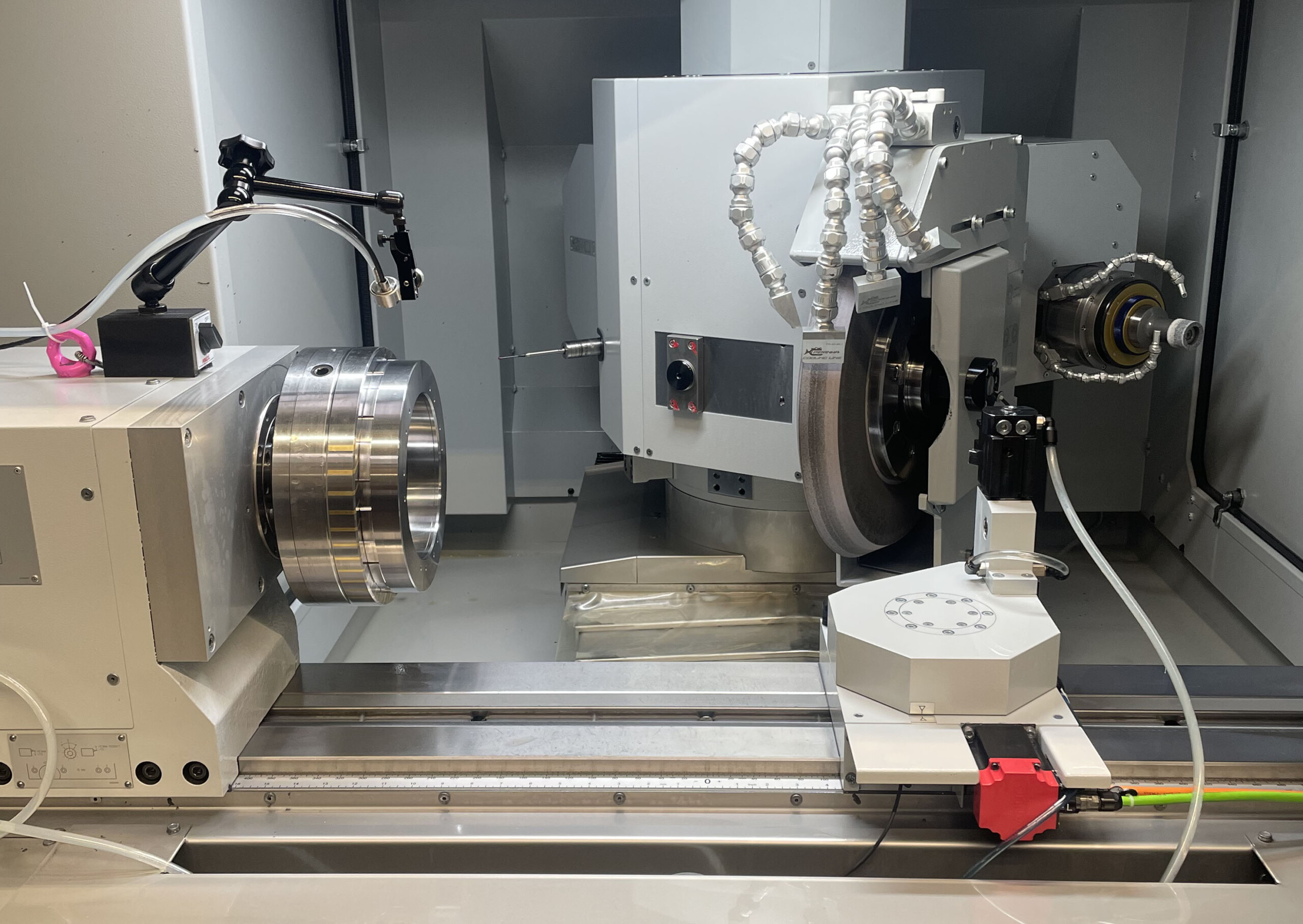

The KELLENBERGER VM 1000 is optimized for flexible, universal internal and external circular machining of complex workpieces up to a length of 600 mm. The range of workpieces includes everything from the smallest individual parts for car engine injection systems, to ball bearing rings and gears, all the way to hydraulic components and complex parts used in machine tool manufacturing.

The machine features hydrostatic guides on all axes. These highly dynamic linear axes are backlash-free and enable positioning accuracies in the nanometer range. This allows for ultra-precise grinding with maximum repeatability and machine availability throughout the entire service life of the machine.

A key highlight is the presence of two high-precision hydrostatic B axes – the B1 axis with a spindle turret and the B2 axis with a table turret – which also carry out all necessary movements of the dressing and measuring systems.

The spindle turret on the B1 axis is equipped with a uniquely compact grinding spindle head featuring a flexible spindle arrangement. This enables optimal positioning of spindles and measuring sensors, allowing for the machining of virtually any workpiece and the execution of multiple internal and external grinding operations in a single clamping.

The KELLENBERGER VM 1000 is equipped with an external grinding spindle and three internal grinding spindles

Fast and easy programming with the BLUE Solution Control Software

The two grinding machines, K100 and VM1000, are equipped with Kellenberger’s innovative BLUE Solution control software, developed specially for grinding applications. It is intuitive and easy to use, even for less experienced operators. The touch-screen layout is clear and user-friendly, allowing controls to be quickly identified and selected. During data entry, the operator receives maximum support. A plausibility check flags incorrect inputss, allowing the operator to make adjustments as needed.

Machine operator Francesco Brescia appreciates the BLUE Solution control software for its ease of use and the flexibility of its programs

The clear structure into three main areas – Set-up, Programming and Production – along with three auxiliary areas – Diagnostics, Settings and Functions – makes configuring a machine for a new production process easier than ever before. The BLUE Solution software includes modules for non-circular and thread grinding, as well as a regrinding cycle.

In addition to the high-performance grinding machines of the latest generation, two older Kellenberger U1000 machines in the grinding department continue to impress with the high quality of the workpieces produced on them. “The U1000 machines require a bit more grinding experience compared to newer models,” says Mike Zinapold. “But our well-trained machine operators still achieve micron-level precision on these machines!”

The two older Kellenberger U1000 machines still grind with micron-level precision. Machine operator and grinding expert Ralf Leopold plays a major role in that.

Kellenberger machines impress us above all with the high quality of the machined workpieces. Whether it’s the machine kinematics, the linear direct drives, or the hydrostatic axes – everything reflects the same level of care and precision in Goldach as we apply in our own company,” concludes Mike Zinapold. “What we also truly appreciate about Kellenberger is their service expertise and training support. Every employee does an excellent job, the service staff on the phone are highly knowledgeable and often solve minor issues immediately. And with Holger Seitz, our dedicated sales representative, we have had an exceptionally competent point of contact for many years. “

Genuine Sterman only with the “Picea”! The stylized spruce marks the original