High-precision grinding ensures low noise level in BEVs

When an electric vehicle glides silently along the road, this is partly due to the motor, which, unlike a combustion engine, makes no noise. Gear measuring machines ensure that the gearbox also operates quietly. Munkert GmbH in Altdorf near Nuremberg, Germany, manufactures and supplies components and assemblies for these machines, among other things. Their high quality is ensured by the KELLENBERGER K1000 premium grinding machine.

When the gear measuring machines from Frenco GmbH perform their work, a component from Munkert GmbH usually typically ensures the desired precision. The company has for many years been a supplier of components and assemblies for the high-precision machines that inspect gears in electric vehicle transmissions for irregularities.

Since its founding by master craftsman Karl Munkert in 1963, Munkert has established itself as a high-performance specialist in high-precision parts with great variety, particularly for customers in the fields of metrology, fixture construction, mold and tool making, as well as mechanical engineering, medical technology and motorsports. Many customers are regionally based companies. The materials processed include steel, stainless steel, aluminum, copper, titanium alloys, and plastics. The company primarily produces individual parts and small batches.

Master turner Wolfgang Munkert took over the business from his father in 1995, successfully continuing its operation before passing it over to the third generation of the family enterprise in 2021. Son-in-law Pasquale Barone and daughter Eva now ensure the continuity that defines a successful company. “We still consult on important matters,” says Managing Director Pasquale Barone about the strong collaboration with Wolfgang Munkert. “This included the acquisition of the KELLENBERGER K1000 grinding machine. Which has exceeded our highest standards of precision, that have characterized our company for decades.” That the grinding hall is fully air-conditioned in order to achieve this level of precision goes without saying.

Still a great team: Wolfgang Munkert and son-in-law Pasquale Barone, who now runs the business, standing in front of the new KELLENBERGER K1000.

Munkert’s positive experience with Kellenberger grinding machines goes back a long way. Over 30 years ago, the company acquired a Kellenberger U600 from their customer Frenco. The high quality of the manufactured parts was so convincing that a few years later another U600 was purchased. Both machines are still in daily use today. “My father designed the dressing device for the machine so that we didn’t always have to dress at the tailstock. Of course, the parts for it were manufactured in-house, and it still works perfectly to this day,” recalls Wolfgang Munkert. “Compared to today’s machines, a little more grinding experience is required here, but our operators are highly skilled professionals – specialists, master craftsmen, and technicians – and the two machines still grind to micron precision!”

The CNC era at Munkert began in 1985 with the purchase of a CNC milling machine, followed by two CNC lathes. In 1997, grinding machines followed with the acquisition of a Kellenberger KEL-Varia equipped with a Kelco control. “The Kellenberger representative from the greater Nuremberg area gave us good advice at the time. And since the KEL-Varia was a demonstration machine, the price was also attractive.”

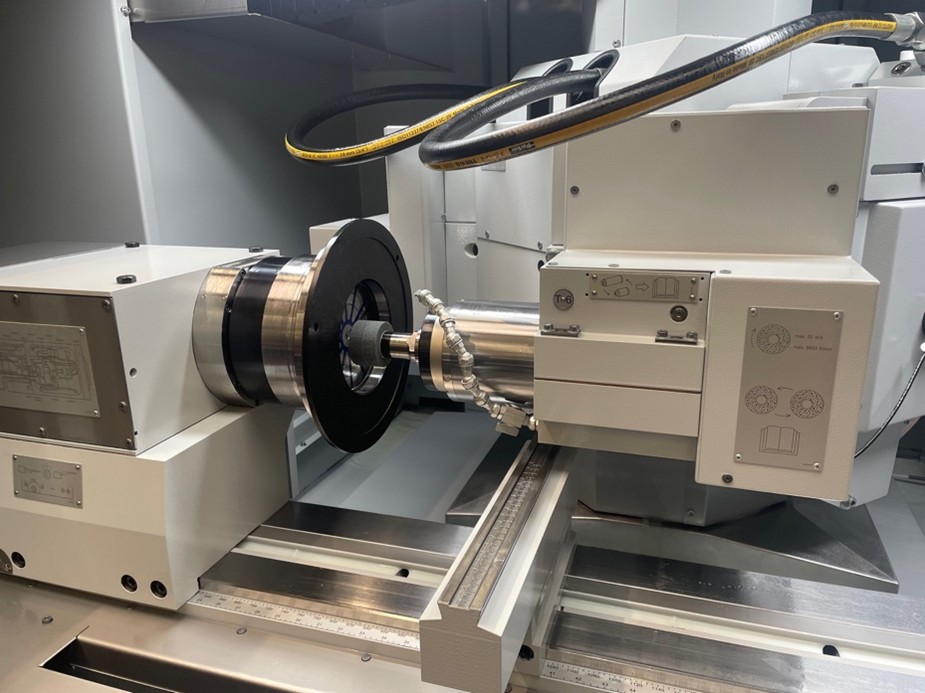

In 2021, Munkert decided to invest in a KELLENBERGER K1000, the most powerful grinding machine in Kellenberger’s premium segment, partly for capacity reasons and partly due to the growing performance requirements. This machine series is designed to meet the high standards of precision manufacturing for prototypes as well as small and medium-sized series. A solid machine table with a reinforced machine bed provides very high static and dynamic rigidity and stability, both of which are key factors for exceptional machining and surface quality, high precision, and significant productivity.

The KELLENBERGER K1000 is equipped with hydrostatic guides on all main axes for maximum shape accuracy for grinding tasks with interpolating axes. The CNC-controlled B-axis for the grinding head is hydrostatically mounted, making it completely wear-free. It features a direct drive with a water-cooled high-torque motor and an angle encoder with a resolution of 0.1 angular seconds. This allows the turret grinding head to swivel approximately three times faster and position with an accuracy of less than one angular second. This design significantly reduces down time and increases productivity, especially when machining processes require different grinding wheels to be swiveled in.

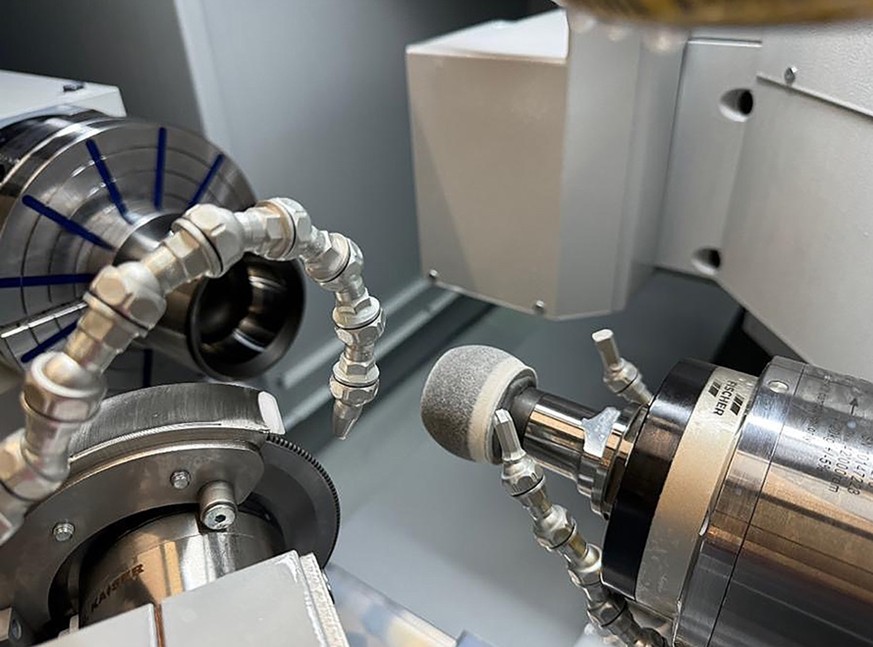

Machine operator and trained mold maker Marc Wagner has been with the company since 2017. He greatly appreciates the user-friendly operation of the BLUE Solution.

From the optionally available center widths of 1,000/1,600 mm and center heights of 200/250 and 300 mm for the KELLENBERGER K1000, Munkert chose a machine with a center width of 1,000 mm and a center height of 250 mm. Among the more than 30 different grinding head variants with external and internal grinding spindles available as standard for the KELLENBERGER K1000 to cover any machining requirement, Munkert selected a grinding head configuration with two external grinding spindles and two high-frequency internal grinding spindles with maximum speeds of 42,000 rpm and 60,000 rpm, respectively. The machine is equipped with a roll dresser for precise internal contours, an in-process measuring system, and a fluid sensor.

In the past, grinding workpieces with micron precision, required an experienced grinder at the machine. Today, the KELLENBERGER K1000, equipped with the powerful BLUE Solution control software, ensures outstanding precision and excellent results in both circular and non-circular grinding.

Quick and easy programming with the BLUE Solution control software

The KELLENBERGER K1000, like all Kellenberger machines, is equipped with Kellenberger’s innovative BLUE Solution control software, specifically developed for grinding operations. The software is intuitive and logically designed, making it easy to use even for inexperienced operators. The control elements are clearly arranged on the touchscreen, allowing for quick navigation and selection. During data entry, users receive maximum support. Plausibility monitoring indicates incorrect entries, allowing the operator to make adjustments. The clear structure into three main areas – Set-up, Programming, and Production – and three supplementary areas – diagnostics, Settings, and Functions – makes setting up the machine for a new production process easier than ever. The BLUE Solution software includes modules for non-circular and thread grinding as well as a regrinding cycle. For more complex grinding tasks, such as thread grinding, the BlackCam variant is selected.

The KELLENBERGER K1000 was delivered and commissioned in mid-2024 and is already working at full capacity. Four employees operate the machine in shifts, including Pasquale Barone, who enthusiastically shares his experience: “We are very satisfied with the accuracy of the KELLENBERGER K1000. The machine is switched off in the evening and when we turn it back on the next morning, it immediately delivers accuracy within 2 µm!”

Still performing its job with micron precision to this day: one of the two U600, that are still in use at Munkert

Pasquale Barone’s conclusion is accordingly positive: “With the KELLENBERGER K1000, we stand out from the crowd of suppliers and have become even more competitive thanks to the latest technology the machine offers,” he says. At Munkert, there is particular satisfaction with Kellenberger’s customer focus, which also extends to the areas of service and training. The training sessions, in particular, greatly impressed Pasquale Barone: “The on-site training at Kellenberger in Goldach was conducted in small groups, the BlackCam training even in groups of two. The trainer was very attentive and answered all our questions. We felt truly well informed afterwards.” Wolfgang Munkert adds: “At Kellenberger, it’s not just the machines that are outstanding, but the entire company is as well.”

Training manager Andreas Petrassi ensures that every Kellenberger customer masters their machine and its control system.