The Kellenberger machine range offers a wide variety of outstanding solutions for grinding, turning, and milling in all industries where maximum precision and flexibility are required. Our series range from universal grinding machines for complex machining tasks to specialized applications. This means we can offer the right solutions for even the most demanding industrial sectors.

The KELLENBERGER K series is characterized by a wide range of configuration options for a variety of grinding operations in all industries. The “KELLENBERGER and “KELLENBERGER were developed for the high demands of precision manufacturing of prototypes and small and medium series, e.g., in mechanical engineering, tool and mold making, the electrical industry, and the aircraft industry.

The “KELLENBERGER is optimized for flexible, universal internal and external cylindrical grinding of complex workpieces. The variety of parts ranges from the smallest individual parts for injection systems in car engines to ball bearing rings and gearboxes to hydraulic components and complex components in mechanical engineering, such as spindles.

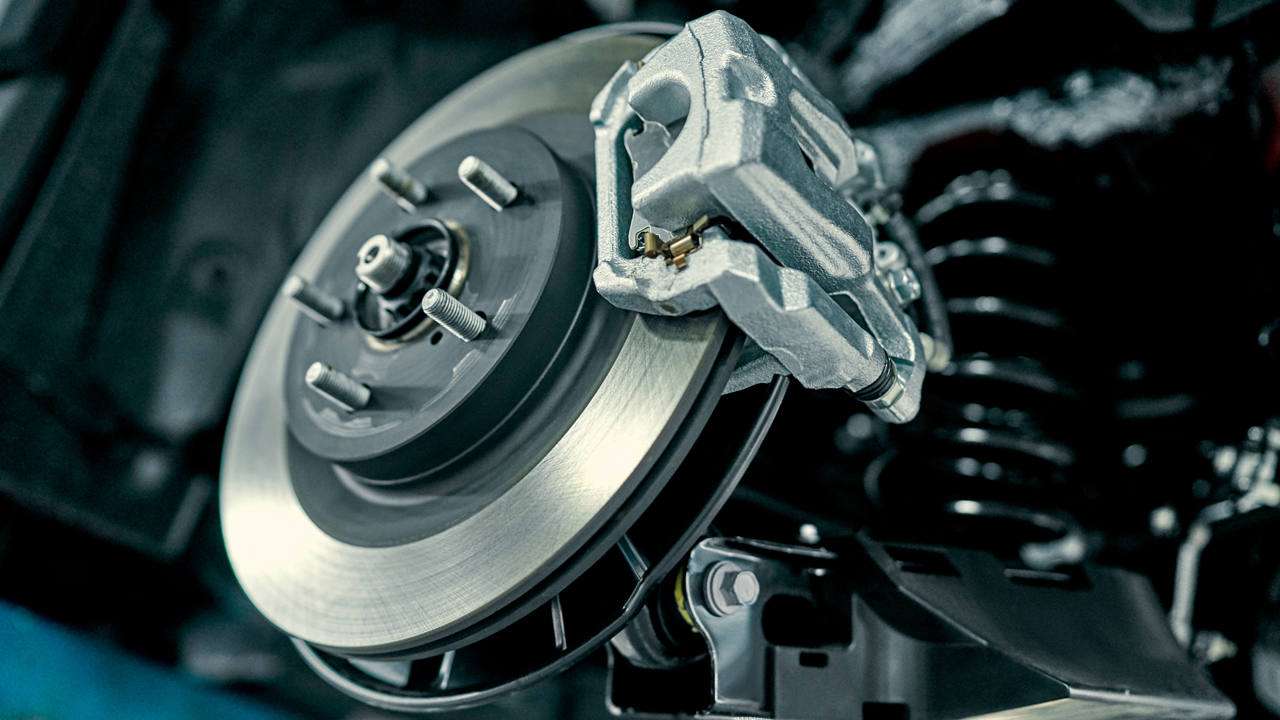

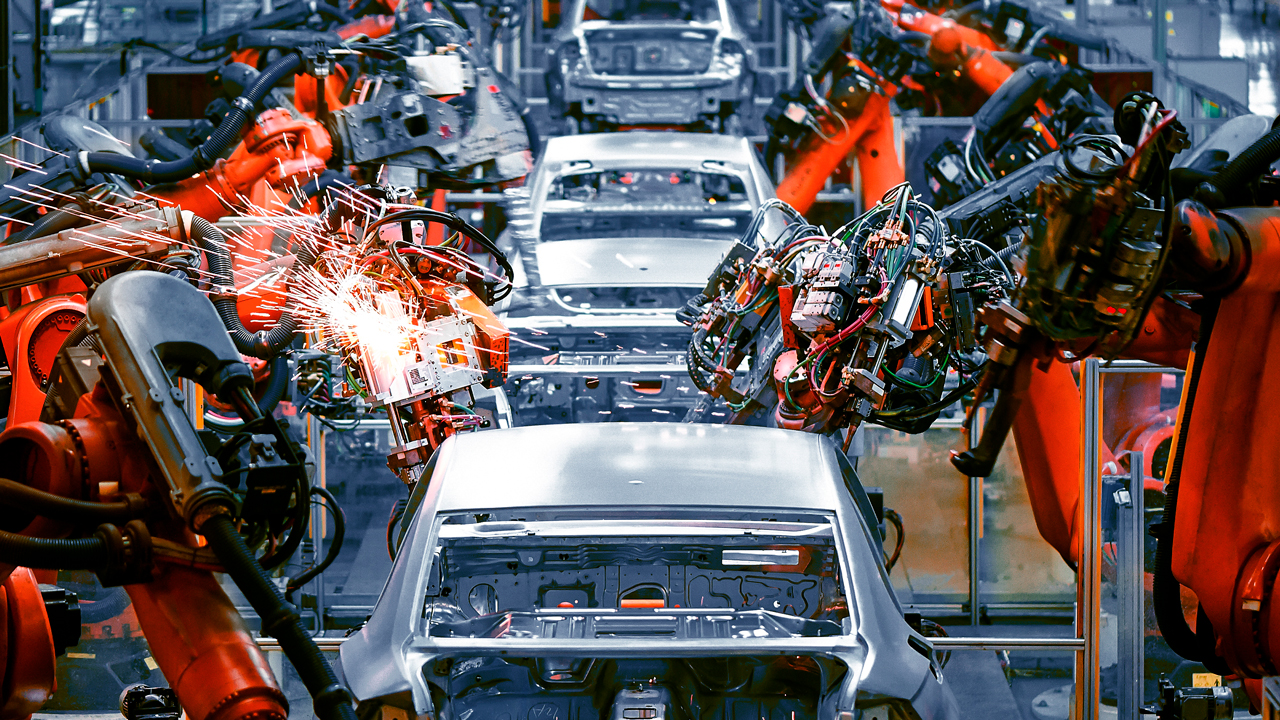

The system solutions in the KELLENBERGER T series were developed for the numerous application requirements involved in machining parts, particularly in large-scale series production. They include automatic feeding, measuring devices, and other additional operations as required. Automation solutions range from small integrated handling systems to complex systems with autonomous cells. The customer-specific turnkey solutions are supplied to automotive manufacturers and their suppliers, among others, and increasingly also to other industries that produce large quantities with the highest precision.

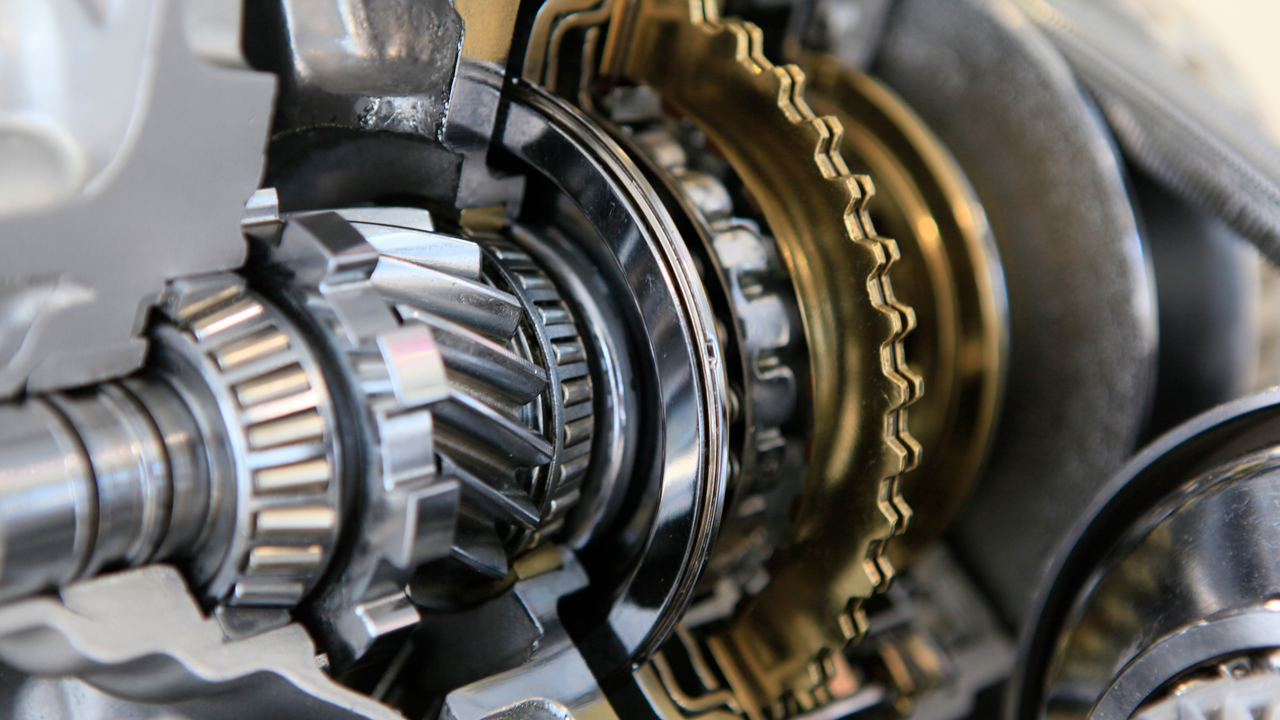

Kellenberger SP hard turning machines can be used in the production of workpieces made of hardened steel instead of grinding machines. They achieve high-precision surfaces, e.g., for gear components and other powertrain components, valve seats, pistons, cylinder liners, and constant velocity joints. An optional grinding device enables turning plus smaller grinding processes in one machine.