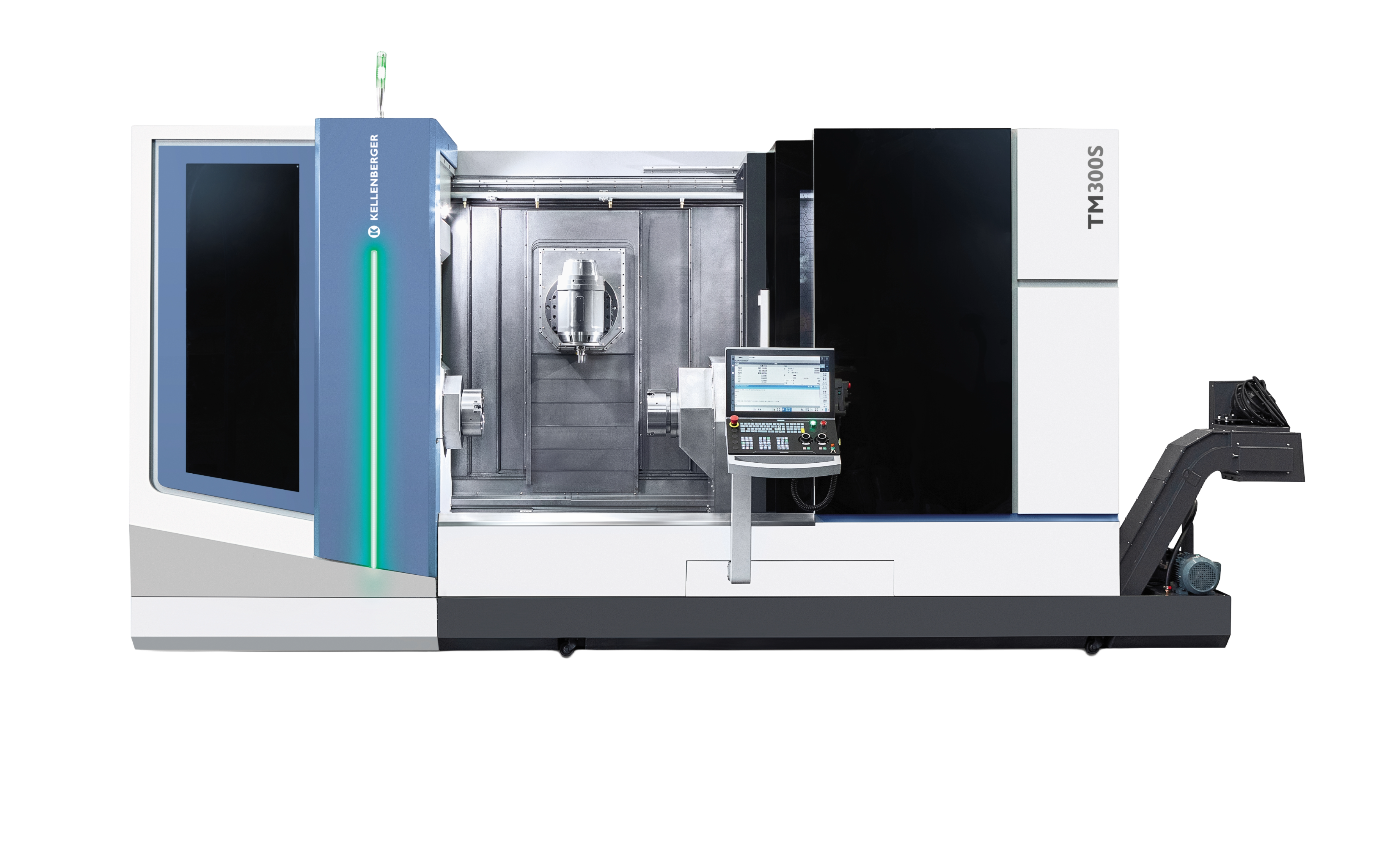

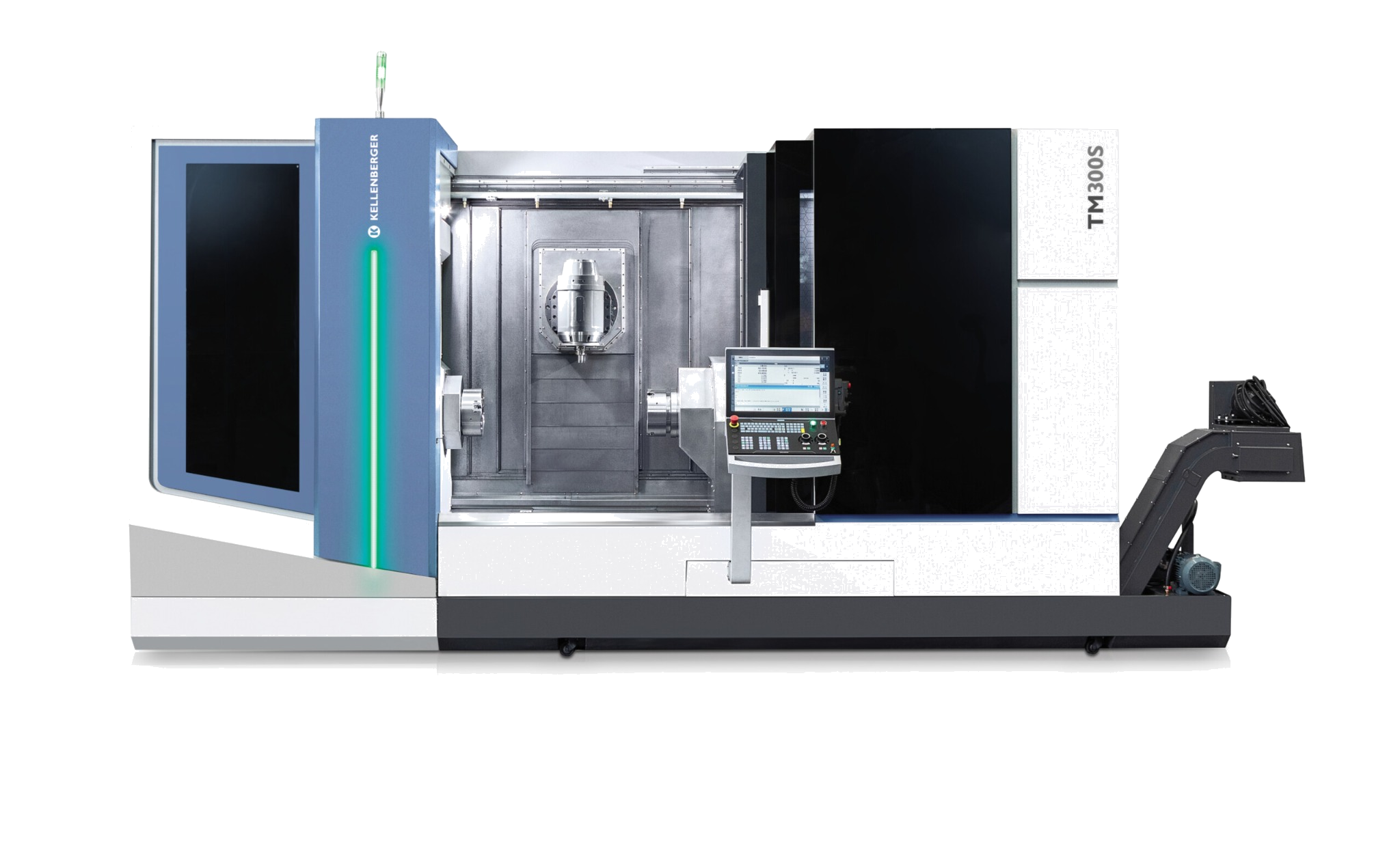

The KELLENBERGER TM300 is a state-of-the-art 5-axis turning-milling center with full closed-loop control. It combines powerful milling and turning capabilities in a single machine, making it ideal for applications in precision engineering, aerospace, medical technology, and general mechanical manufacturing.

KELLENBERGER TM300

FEATURES AND OPTIONS

Key Highlights

- 5-axis simultaneous machining / 6-sided machining in a single set-up

- Orthogonal Y-axis with 300 mm travel for extended machining range

- B-axis with 240° swivel, direct drive for high precision and fast response

- High-torque main spindle (A2-8) with 3,500 rpm and 600 Nm torque

- Milling spindle HSK T63 with 12,000 rpm and 100 Nm torque

- Sub-spindle (TM300S/ST) with 3500 rpm and 477 Nm torque(TM300S)/ 433 Nm torque (TM300ST)

- 40-position tool magazine with automatic tool changer

- Siemens SINUMERIK One with 22″ touchscreen and optional Digital Twin

- Servo tailstock MT5, integrated cooling, air and lubrication systems

Optional Features

- Digital Twin for simulation and optimization of machining processes

- Collision detection, 3D simulation, graphical programming

- Sub-spindle (TM300S/ST) and lower turret (TM300ST) for maximum productivity

TYPICAL APPLICATIONS

- Precision shafts and bushings

- Complex rotationally symmetrical parts

- Medical implants

- Aerospace components with high surface quality requirements

TECHNICAL SPECIFICATIONS (EXCERPT)

KELLENBERGER TM300

KELLENBERGER TM300S

KELLENBERGER TM300ST

Max. turning diameter

Max. turning length

Main spindle speed

Milling spindle

Tool magazine

Machine weight

Dimensions

Download

Anfrage

Ich interessiere mich für eine Maschine